How to Elevate Supplier Risk Assessment with AI

When a food safety incident unfolds, and food manufactures are faced with the economic and reputational impact of such events, they have to look inwards to their processes. Central to these are the systems, processes and protocols in place for assessing the food company’s suppliers.

Fostering a successful business relationship and effective communication with their suppliers is paramount for streamlining these processes, as food companies look for consistency and trust from their suppliers as well as an in-depth understanding of their products, knowledge which they then share with them. While effective communication is highly important, supplier evaluation and assessment are cornerstone processes for food manufactures to have a great understanding of their suppliers, their products’ potential hazards in order to be able to take corrective actions to mitigate risks.

However, keeping track with numerous suppliers from around the world can be a mountainous and extremely time-consuming task that can leave companies scrambling to keep up, and exposed to unforeseen risks.

Process Automation and Continuous Monitoring are a Necessity

Supplier assessment can be a very challenging process for food companies. When it comes to assessing and evaluating their suppliers, food manufactures are bogged down by the sheer amount of data (about food safety incidents, lab results, audits, inspections etc.) kept in numerous spreadsheets from disparate sources housed in different silos which is impossible to combine and correlate. Add to that, the requirement to track and trace the safety and quality of history of each supplier globally (traceability) which makes the often manual process quite complex, time-consuming and prone to data loss from the involvement of multiple different systems and people.

It becomes all the more apparent that food companies would greatly benefit from automating the process by utilizing a solution that would allow them to collect and correlate all supplier and product data in a single unified environment. This would provide them with actionable insights as well as the opportunity to monitor worldwide food safety events including their suppliers’ performance.

Boosting Supplier Assessment and Evaluation with AI

The applications of AI have been previously discussed when it comes to food safety. But, how can AI help food manufactures continuously monitor the food safety performance of all their suppliers to avoid food safety incidents?

Supplier Food Safety Performance Assessment & Evaluation

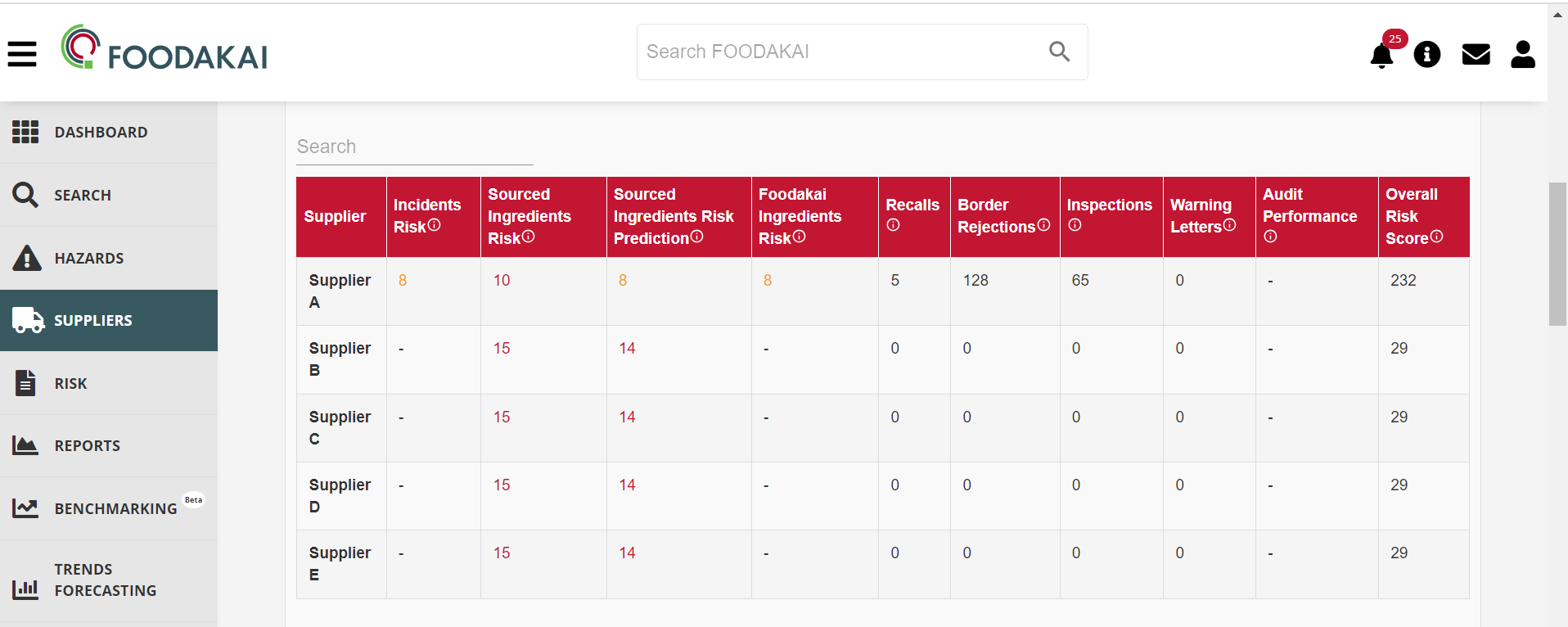

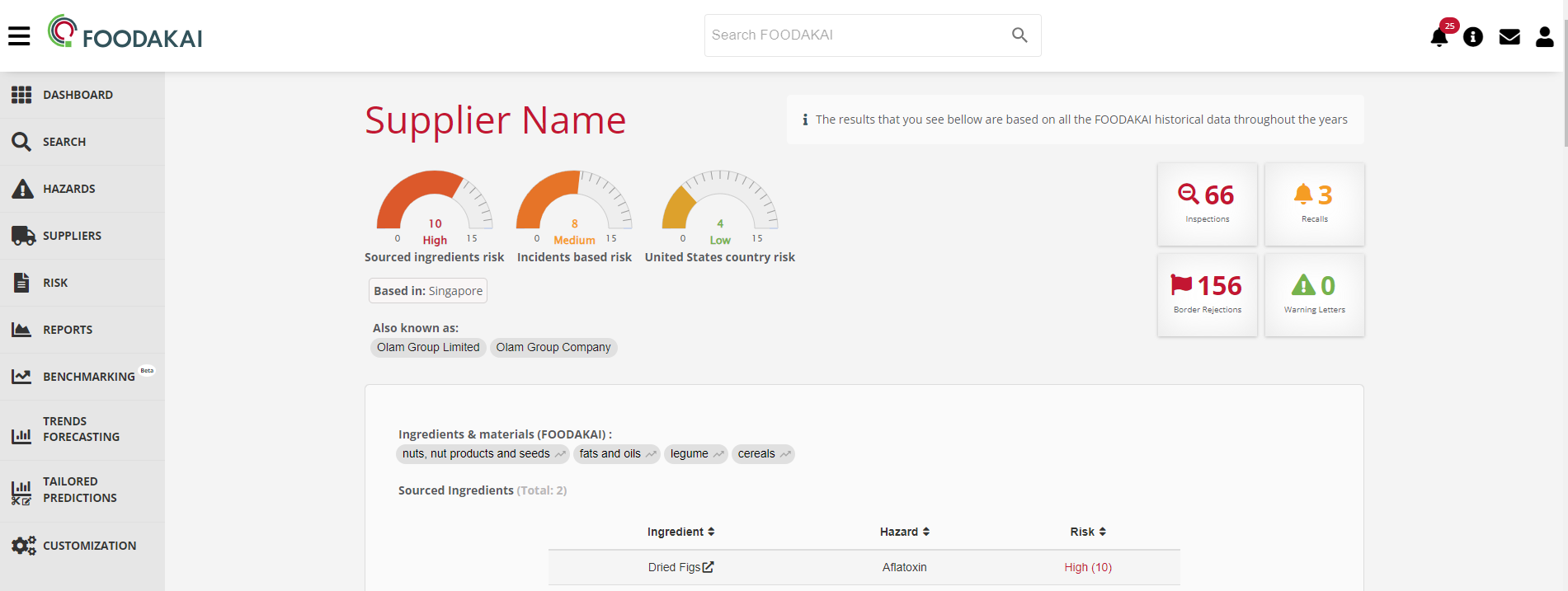

Utilizing FOODAKAI’s AI-powered platform, food manufactures can discover the food safety risk performance and risk score of every single supplier in their supply chain based on the number of incidents they have been involved in, their sourced ingredients, and the country of origin of the supplier. This way, supplier selection can be streamlined and simplified by having actionable insights and all prospective suppliers, compare them based on their food safety performance.

Additionally, with detailed information on the risk performance of suppliers, (including drilling down to view to see the Inspections, Recalls, Border Rejections and Warning Letters) food companies can critically enhance their risk assessment and evaluation processes of not only new but also existing suppliers in their supply chain so they can take additional measures if needed.

Discover Vulnerable Food Products & High-Risk Geographic Origin of Ingredients

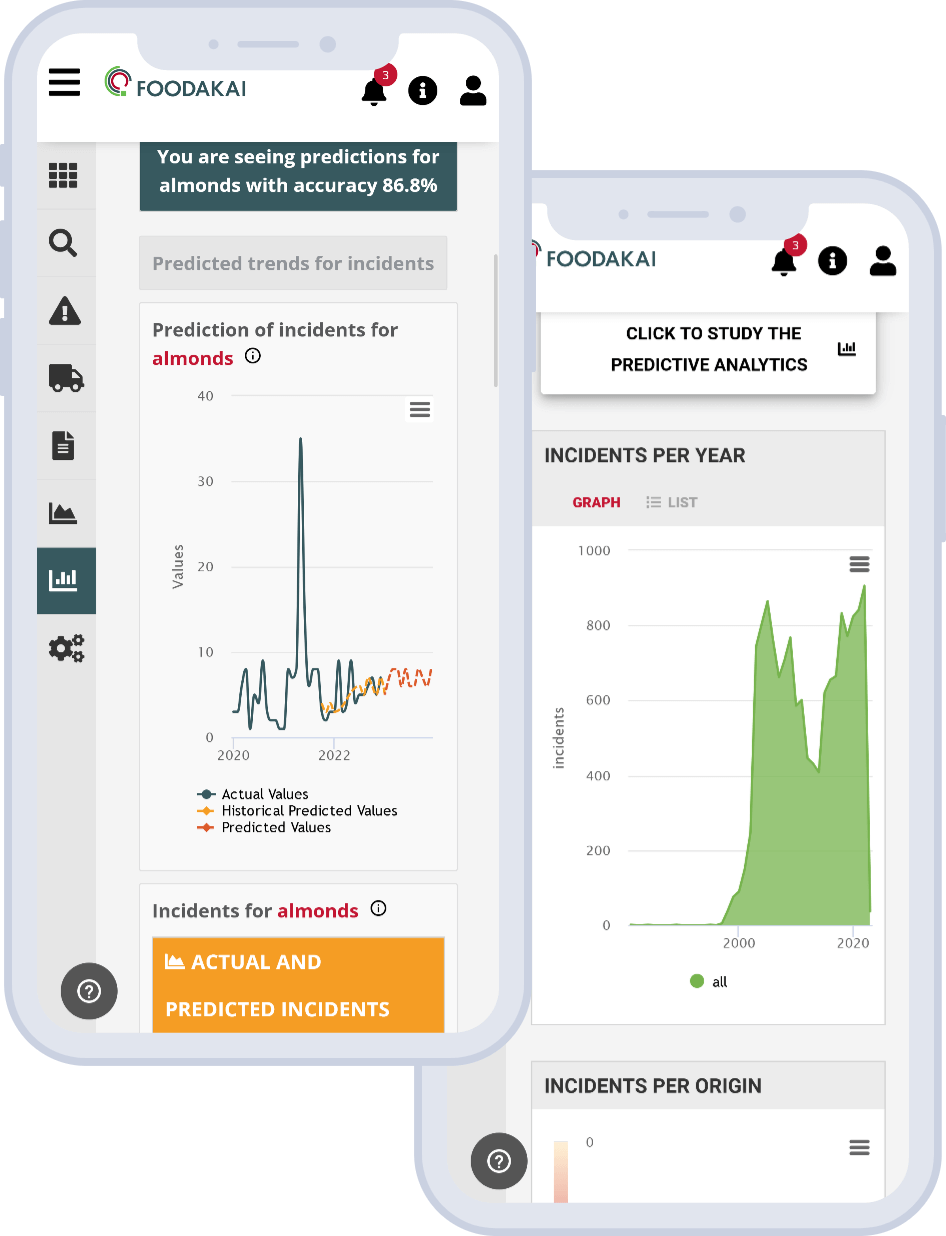

Through the platform’s Suppliers Dashboards, Supplier Profile and Trend Forecasts offerings, food manufactures can investigate forecasted safety trends in geographical areas of interest for their key ingredients or finished products in correlation to their suppliers. For example, risk managers can discover the top forecasted risk for their suppliers according to the ingredients sourced from them.

Furthermore, they can have an overview of the countries that are expected to have increased risk for incidents for their key ingredients which are sourced there or the suppliers that are located in the area. With this data then, risk managers can have an extended overview of potential risk for their existing or new suppliers as well as regions of interest for their selected ingredients. This way they can evaluate them and take preventive measures such increasing inspections of their suppliers or performing additional audits and lab tests.

Identify Emerging Risks, Formulate Mitigation Strategy & Enhance Sustainability

Food manufacturers, by accessing the platform’s Suppliers Dashboards and Trend Forecasts on top hazards for suppliers that are expected to be on the increase for your key sourced ingredients, can identify early weaknesses and emerging risks in their supply chain. Having and clear view of where risk lies in regard to unforeseen risk and their suppliers, they can take proactive steps to mitigate future risk, by creating a comprehensive sampling strategy throughout their supply chain and take immediate corrective action.

As food companies gain expanded knowledge on what risks and hazards might impact their supply chain, they will be able to safeguard their products and avoid food safety incidents to protect public health by providing consumers with safe food. In turn, the reduction of ensuing food waste from food safety incidents will help them meet their sustainability goals.

Through FOODAKAI’S continuously monitoring of the food safety performance of all suppliers and the forecasted hazards associated to sourced ingredient from them, food companies can perform real-time assessment and discover potential risks to their supply chain.

If you want to know in more detail how FOODAKAI can help you book a call with us today.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.