“AI …. can help us see trends faster and apply more proactivity in these (food safety) spaces”

In our effort to validate the greatest challenges that food and beverage companies face, we thought it necessary to discuss with professionals at the heart of these industries in order to have a clear view of where these challenges lie. By understanding what these challenges are, then we can begin the process of tackling them, effectively driving the industry forward.

For this reason, we decided to invite Nia Owen-Cortez, VP R&D Quality Assurance at Mondelēz to discuss about:

- What in her opinion are the biggest challenges for the food safety industry,

- What’s needed in order to face the challenges,

- New technologies and AI and how they can help strengthen food safety and risk prevention measures

- What are the roadblocks when it comes to adopting such technologies

Nia Owen-Cortez, Vice President of Quality at Mondelēz accepted our invitation to offer her insights through a short interview. With over two decades of experience in the food safety and quality assurance industry for major food companies worldwide, Nia joined Mondelēz in 2011 and currently resides in Zurich. She specialises in HACCP programmes development and implementation as well as providing process -related microbial advice and problem solving in the area of product contamination.

In the interview, Nia noted above all the challenges of supply chain disruptions due to various factors that are not part of the supply chain food & beverage companies can easily control, the lack of skilled workers, the soaring prices of commodities, as well as the benefits of applying AI in food safety for streamlining monotonous time-consuming tasks, while increasing proactivity and all the associated blockers.

Nia, what are the biggest challenges you are currently facing regarding food safety?

In my opinion it will be supply chain disruption over all. This disruption could be caused by a number of factors such as raw material shortages due to crop fails, leading to Food Adulteration or more issues with contaminants, issues with transportation/bulk transport/shipping leading to adulteration or inadequate conditions – much of this is invisible to food manufacturers as it’s not a part of the supply chain we can easily control.

Then challenges finding skilled workers to operate facilities due to non-attractiveness of sector leading to it being difficult for companies to maintain fundamental basic conditions due to staff turnover, and the soaring prices of commodities meaning that the food industry will be grappling with profitability and may not be able to invest adequately in basic infrastructure and utilities as well as the employees as I mentioned.

It is also the fact that so many material supplies are common across many sectors, so that if there is an issue with contaminants for example, a large swathe of the food manufacturing industry is impacted. So, in my mind it is more about the context that will increase the risk and not one thing in particular.

In the context of the European market?

Not different from those already mentioned, but in developing countries there are additional challenges such as industrialisation, poverty, drought, famine, war that bring their own risks that ultimately impact the now global supply chain.

In Europe we may face a very difficult operational landscape if the European countries keep shifting away from one unified legislative Food standard, the more different states move away from a standard or take a different interpretation of it, it makes the environment very difficult for pan – European manufacturers to operate. A need to accommodate differences in standards and /or approach if we are shipping goods to country A or country B which may only be a few hundred kilometers apart.

What can be the impact of Artificial Intelligence (AI) and predictive analytics in strengthening food safety management systems?

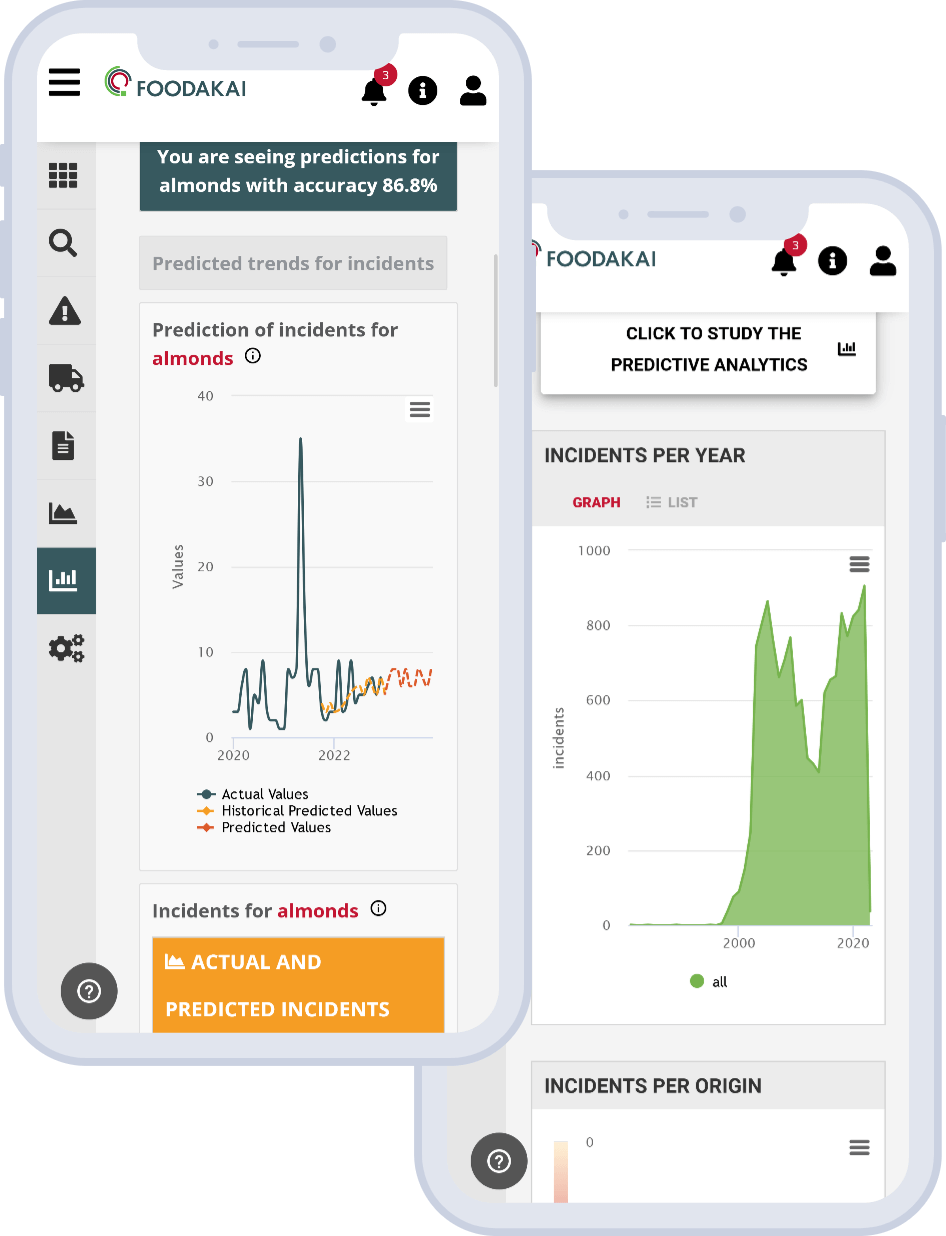

Generally, I think AI can have a very positive impact on so many arduous data management tasks that require a high level of accuracy e.g., Management of Certificates of Analysis, this is a time consuming and monotonous task where AI is starting to be applied with positive results. This is just one example of many tasks that sit in this realm including interpreting lab results, monitoring raw material trends that are linked to food safety issues, consumer complaint trend analysis and many more, I am personally excited that AI can improve in this area and help us see trends faster and apply more proactivity in these spaces.

What are the factors that currently slow down/impede the widespread adoption of AI and Predictive Analytics in food risk prevention?

Generally it is discussions on compatibility and interfacing with existing operating systems, the costing structure of “off the shelf” AI is also not always a good ROI for the food business, and the fact that in itself the food industry is not very digital, so we have some catching up to do to have the right infrastructure to beneficially apply AI to our daily work as we need our data in digital and structured formats.

Want to receive helpful food safety intelligence in your inbox?

Funding for this research has been provided by the European Union’s Horizon Europe research and innovation programme EFRA (Grant Agreement Number 101093026). Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe research and innovation programme EFRA (Grant Agreement Number 101093026). Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.