Case study: The salmonella outbreak in chocolate products explained

Food recalls are the most critical situation that could befall you as a food safety professional. Among the many consequences of recalls, I could highlight putting people’s health in jeopardy, lowering consumer trust in the food industry, and making the food supply chain look unreliable and untrustworthy.

And yet, one question arises: Can AI help us in preventing food recalls?

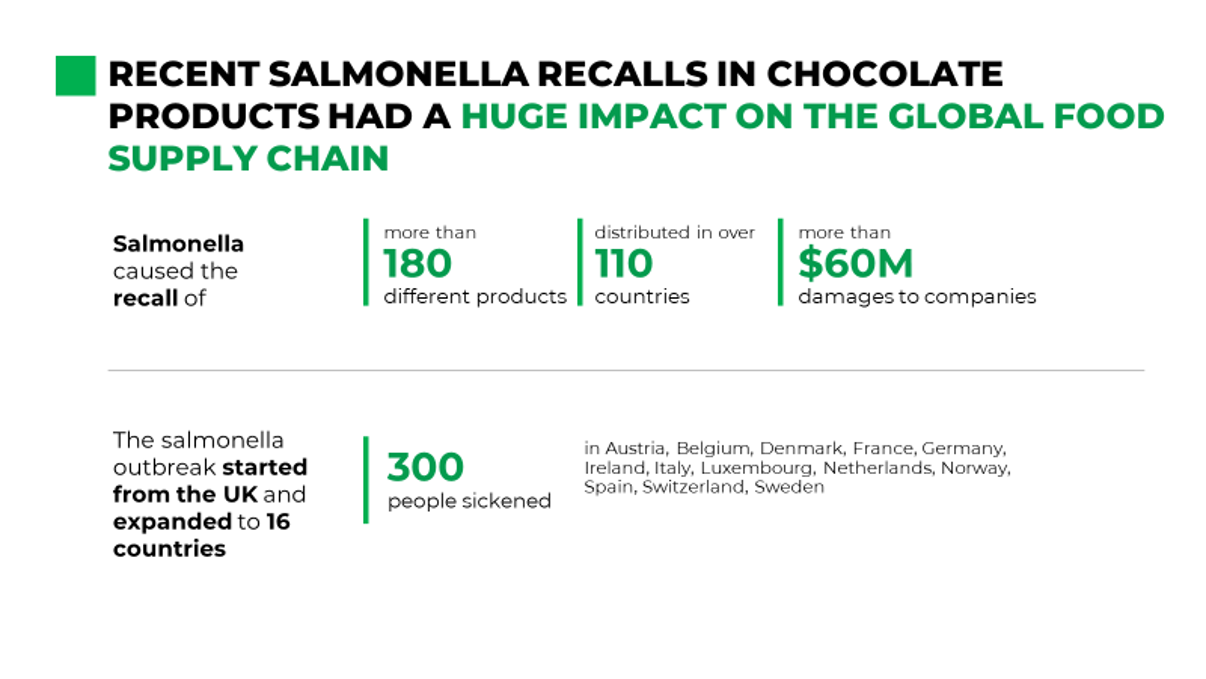

In April 2022, a massive food recall hit the market, when salmonella was detected in chocolate productsmarketed to children, resulting in 300 people falling ill across 16 countries – predominantly young children. Although food safety is advancing every day, such outbreaks are more and more frequent in the past few years. Counterintuitive, right?

Let’s dive deeper into the case of salmonella in chocolate products to see how data science and AI could have helped food safety and quality assurance teams prevent such recalls.

How the outbreak started

At the beginning of April 2022, Ferrero started recalling more than 180 products distributed in over 110 countries due to salmonella contamination. Specifically in this case it was the multidrug-resistant monophasicSalmonella Typhimurium infection.

The initial investigation of the root cause showed that the contamination occurred in a processing step at a manufacturing facility in Arlon, Belgium, where 7% of the global production of Ferrero’s chocolate brand “Kinder” is made. Salmonella was detected on the surface and in residual raw material samples taken from buttermilk tanks.

However, it didn’t end with just Ferrero. Days later Strauss Group, the largest Israeli food manufacturer, started recalling chocolate products because of salmonella contamination. At the end of May 2022, Cargill also voluntarily recalled select lots of multiple chocolate products, also due to salmonella concerns.

What the data says

Because of initial investigation revealed that the contamination did not happen due to incoming materials used as ingredients in chocolate products, but it was introduced in a processing step, this case study is focused on what data tell us about the likelihood of having such contamination in a finished product like chocolate bars. Or rather, the likelihood of such contamination being introduced in the processing steps.

Hazards analysis for the chocolate products based on historical food safety incidents

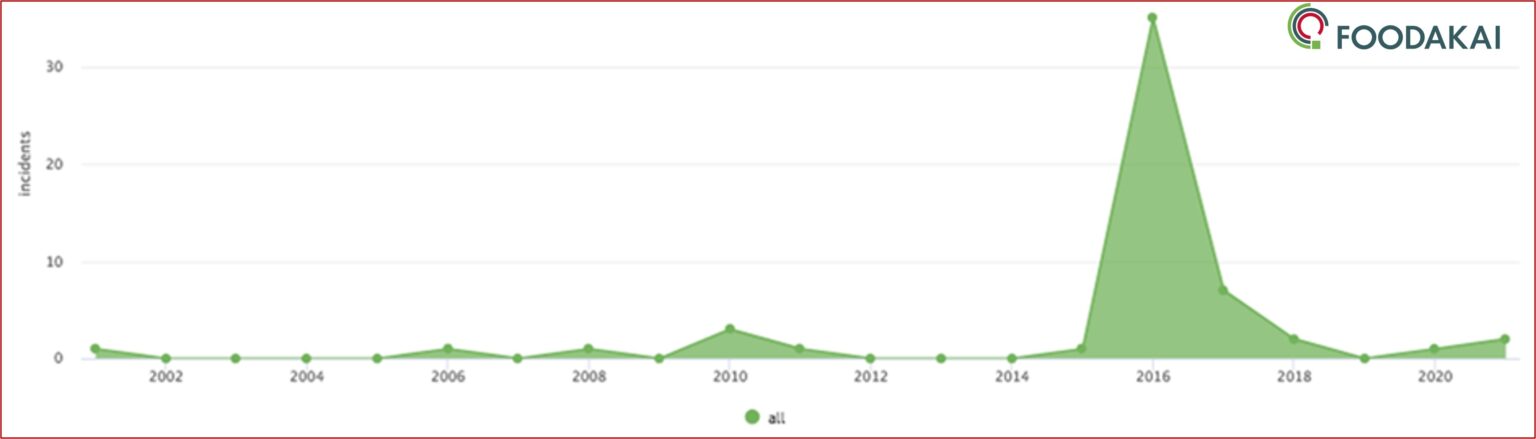

From 1982 until the end of 2021, 57 recalls and border rejections had been recorded, due to contamination of chocolate products with salmonella.

In the chart below you can see the trend of salmonella-related incidents over time. It is very clear that this is not a new issue in the food industry. In fact, in 2016 there was a peak of incidents due to a big recall of milk chocolate products from the United States.

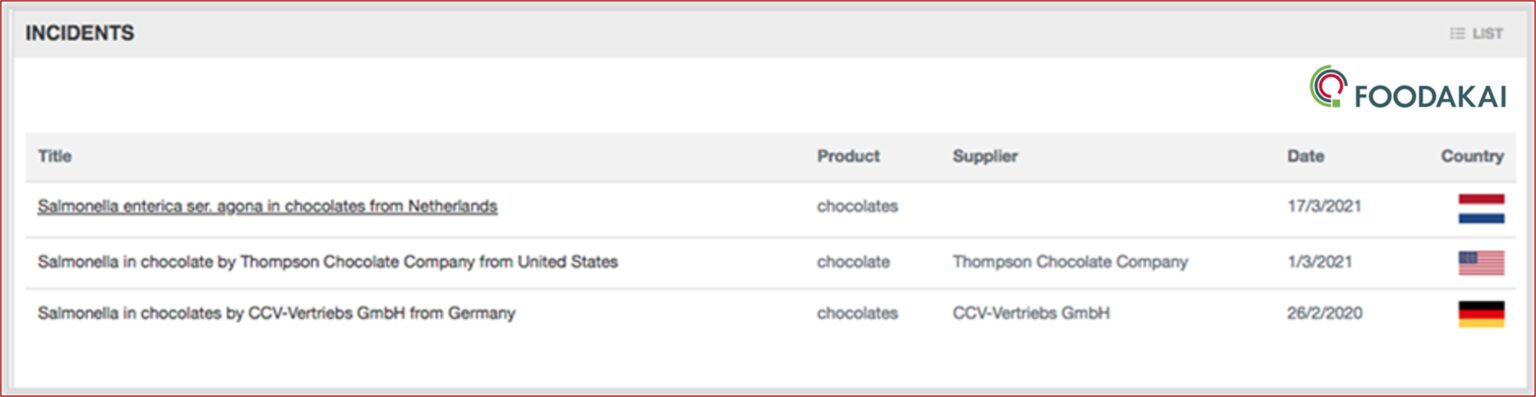

Moreover, from 2019 to 2021 we saw an increasing trend of salmonella cases in chocolate products, having incidents like the ones included in the following table:

High-performance risk monitoring and assessment systems can identify an emerging risk such as a 200% increase in salmonella contamination in chocolate products.

High-performance risk monitoring and assessment systems can identify an emerging risk such as a 200% increase in salmonella contamination in chocolate products.

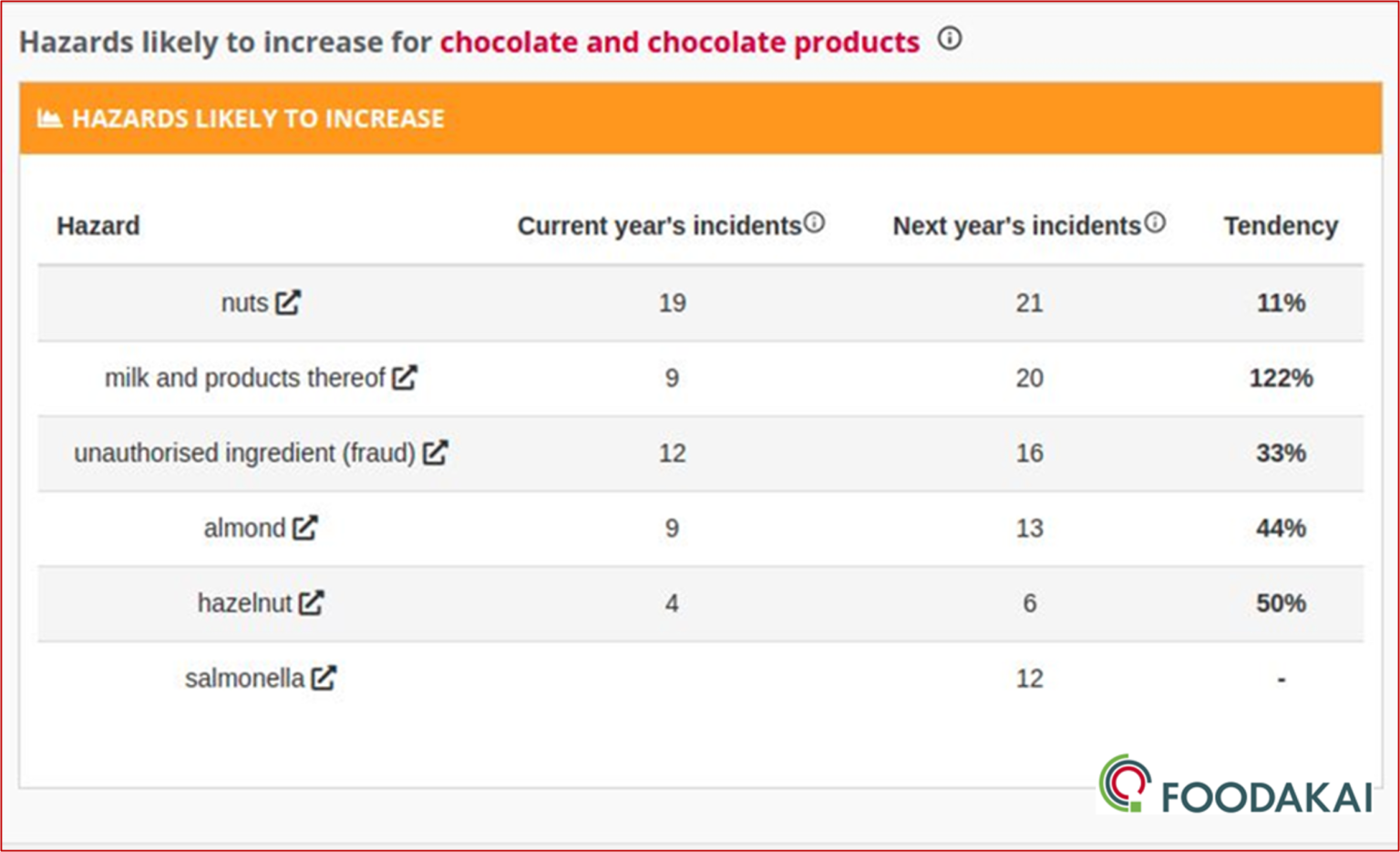

Could food risk predictions have helped us?

Using short-term forecasts for chocolate products, models are able to predict the likelihood of salmonella contamination. It turned out that FOODAKAI’s forecasting algorithms had already predicted earlier on in October 2021, that there would be new food safety incidents in chocolate products due to salmonella in the months to follow.

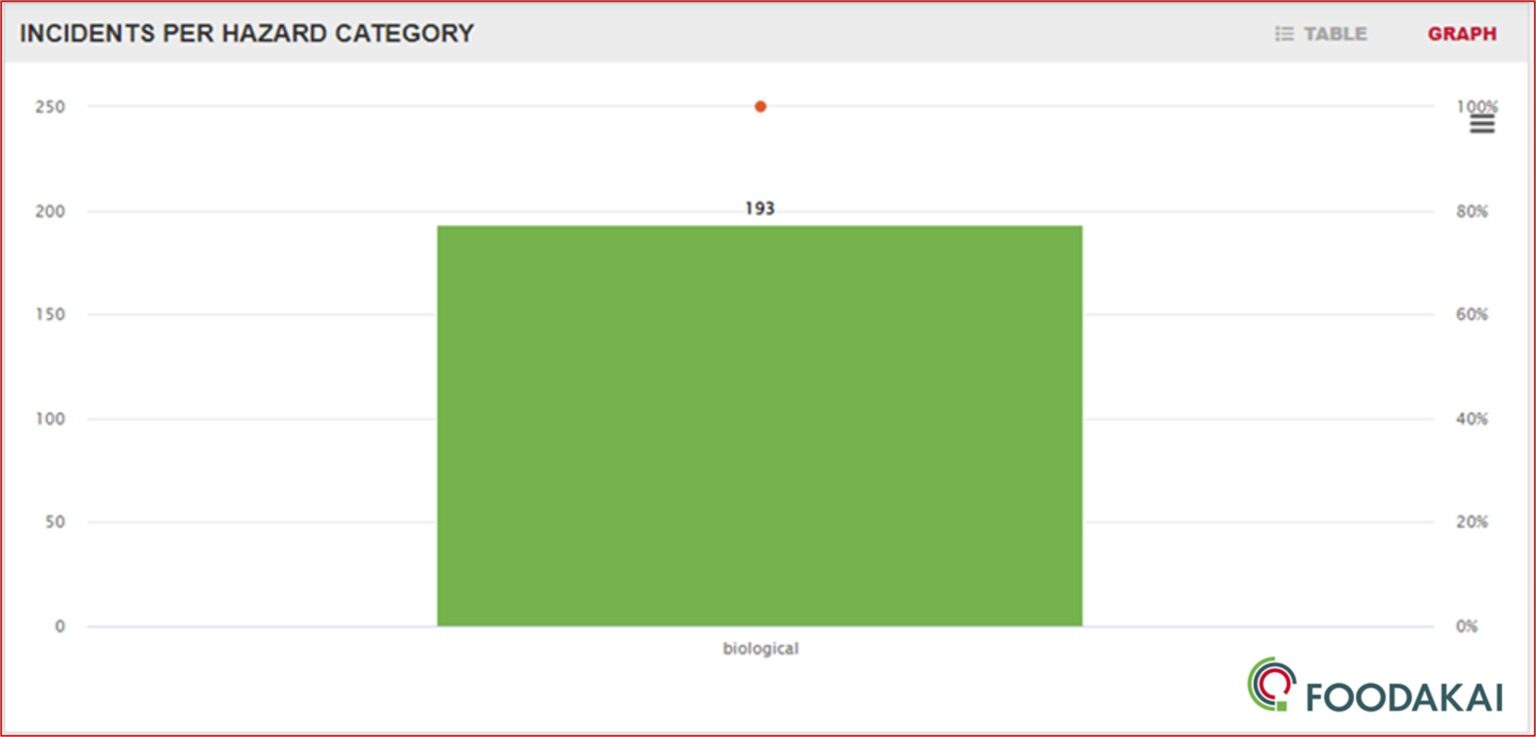

It seems that FOODAKAI predictions were correct. Over the last 3 months (March-June 2022), 193 chocolate product recalls were recorded due to salmonella outbreaks.

Recall Preventive & Risk Mitigation Measures

As mentioned above, this case study is on finished products, not at the ingredient level. So, I have created a brief list of highly recommended measures that a food manufacturing company should take to mitigate the risk of salmonella contaminating its chocolate products, and making it to market:

- Increase the sampling rate for salmonella in your laboratory testing program for finished chocolate products.

- Implement daily monitoring of hazards affecting key ingredients, like cocoa and nuts, customized by role/team/region.

- Use large historical data sets (such as lab testing programs, etc.) & global incident predictions to identify emerging issues and their trends.

- Combine heterogeneous data sources for real-time existing supplier and facility risk ranking to monitor particular suppliers or facilities & increase lab test sampling frequency & change audit plan.

- Make sure that hygiene measures are properly applied in all your facilities manufacturing chocolate products.

- Increase the sampling rate for environmental parameters (get samples from surfaces, machinery, etc.)

- Make sure that your QA teams working in manufacturing facilities are aware of the increased likelihood of salmonella and share salmonella forecasts internally to take immediate mitigation actions.

- Have access to risk predictions for chocolate products for the next 5-10 years.

- Identify the top hazards and vulnerabilities for chocolate products for the last 10 years.

- Organize mock recalls for the high-risk products.

By mitigating risks of a biological hazard like salmonella, we can prevent food recalls that could have a huge financial impact on food companies and most importantly, restore consumer trust in food brands.

You can track the evolution of food safety incidents using a risk monitoring and prediction system such as FOODAKAI, and adapt the necessary mitigation measures, at the very moment you identify an increasing trend.

Start predicting food risks and preventing food recalls today! Let’s talk.