How can AI boost food risk prevention

Ensuring public health through the production of high quality and safe foods that consumers can enjoy is one of the most significant concerns for food companies. In the last few years, the words Artificial Intelligence (AI), predictive analytics have been widely circulated across all industries. The food industry has not been an exception to that, where the application of ΑΙ has been greatly discussed as way of increasing the effectiveness of food safety management systems and therefore improving food safety.

AI’s applications in the food safety industry can be manifold from improving food quality control procedures, upgrading risk assessment strategies, strengthening traceability systems. Perhaps one of the most promising applications of AI is predictive modelling. AI algorithms can, by aggregating and correlating data from various sources, including historical records of food safety incidents, ingredient quality, environmental factors, geographical areas, forecast potential foodborne illness outbreaks and inform food companies of potential emerging risks.

However, food companies remain hesitant about adopting AI and predictive analytics into their processes. They are uncertain about whether such technologies can be trusted and the accuracy of the forecasts and can’t fully understand their application in the food industry.

What makes trusting AI challenging?

When it comes to adopting AI and tapping into the possibilities that predictive analytics, food companies are somewhat unaware of their potential applications. There are various factors that make food companies skeptical about incorporating such technology into their processes. To name a few:

- The reliability of AI models. AI models are dependent on data that is provided to them. If the data is flawed or biased or the sources are not validated and high quality. Then the results might not be satisfactory, and the insights and information drawn might not be actionable.

- The accuracy of the ΑΙ models applied in each supply chain isn’t always appropriately high so that food companies can extract concrete and insightful results. Rather like the lack of high-quality data, the AI models utilized aren’t sufficiently accurate.

- The high cost of implementing AI technologies that could potentially lead to job loss from the ensuing automation of procedures and or processes.

- The fear of data sharing and data security in case of a leak from providing AI with their data.

- The limited data availability due to the reliance on paper processes as many food companies worldwide still have not fully embraced digitalization without the necessary digital data infrastructure with banks of data to feed to AI models. For many companies the process of going digital can seem extremely dauting and time consuming.

- The lack of qualified staff with the necessary expertise that can understand and set up to utilize AI technology withing food companies.

- The lack of resources of food companies.

How can your risk prevention strategies evolve with predictive analytics?

Despite the challenges that come hand in hand with the adoption of AI and predictive analytics in food safety processes that might make food companies wary of utilizing them, there’s tremendous potential for boosting preventive measures. It is strategic for food companies to understand how AI and predictive analytics can be employed to predict and respond to incidents by improving food safety management systems.

AI technology can support the tracking of food from farm to fork, enhancing their monitoring and traceability efforts while offering greater transparency and accountability towards their customers. An AI-powered solution could support food companies striving to improve their food safety and risk prevention methods in the following ways:

- Offer actionable insights on food safety based on high quality harmonized and simultaneously curated data sourced from official public food safety authorities (RASFF, FDA etc.).

- Provide forecasts on incidents and hazards for key ingredients and products in your supply chain that are highly accurate based on selected AI models that offer concrete insights after being thoroughly tested with multiple experiments conducted on them.

- Help existing staff to reduce the time they spend, and resources needed daily to extract information and data about food safety from different sources with ready to use compact results in sharable formats (PDF, Excel) while remaining cost-effective.

- Enable staff to easily utilize the insights gathered in a user-friendly unified platform immediately, with minimal training required and without requiring them to become experts in AI and predictive analytics.

- Empower food companies to carry out risk assessment to identify high-risk ingredients in their supply chain to start moving from a preventive to a proactive stance.

- supplier assessment and risk estimation based on the geographical origin or ingredient they source from to decide on appropriate measures and/or audits, reducing the time needed.

Employing a unified AI-powered platform solution that is user-friendly, customizable to your food companies’ key ingredients and suppliers and offers actionable insights and predictions based on high-quality data and sources can make the difference from being proactive rather than reactive.

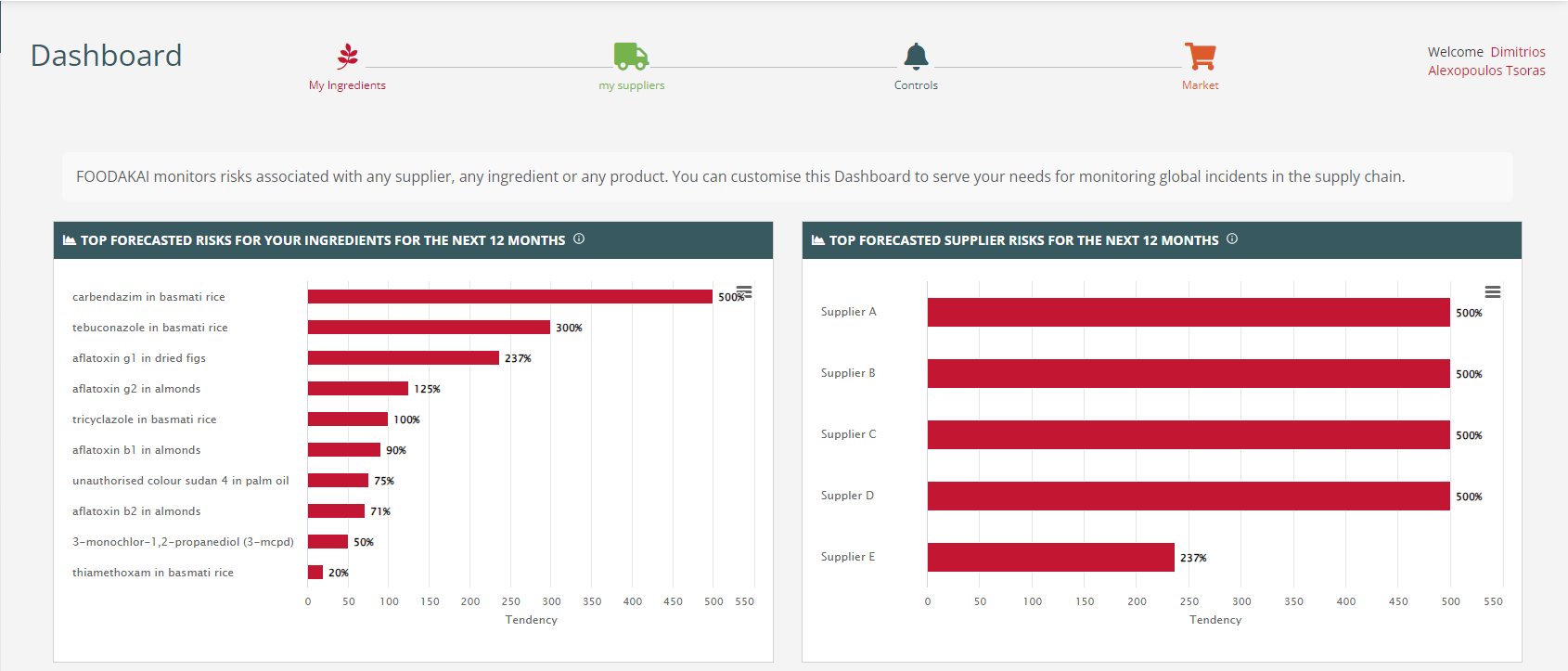

With forecasts tailored to your food company’s specific needs, that are easy to understand and actionable, you can identify immediate and emerging risks to your supply chain and create a more informed risk-based mitigation strategy.

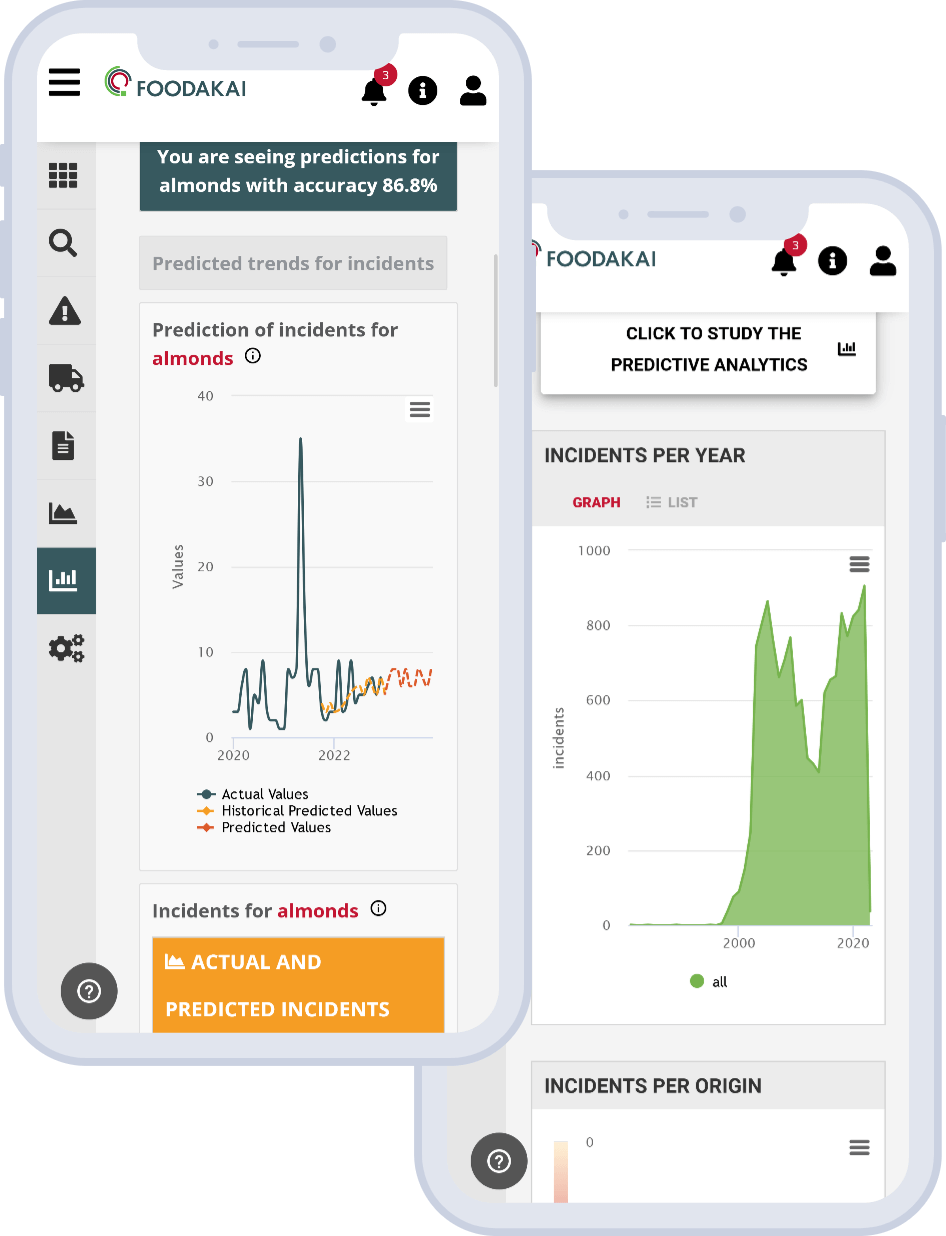

FOODAKAI enables you το take full advantage of the power of predictive analytics to take informed decisions on appropriate preventive measures. Through the platform’s intuitive dashboards, discover forecasts for the likelihood of potential risks and hazards to your key ingredients and suppliers to create a comprehensive and informed risk assessment and sampling strategy.

To know more about how FOODAKAI can help you drastically improve your risk mitigation strategy through actionable hazard forecasts on your key products, begin with a pilot.

Book a call with us today!