Poultry Products: what does the 5-year food safety history reveals about the industry

The poultry industry represents one of the most profitable markets globally, taking a large portion of the food products market share. By 2027, the global poultry market is expected to reach $385.8 billion. Fresh chicken took the second place in retail sales of fresh meat in the US with $15.9 billion, while in the UK the production value of poultry and poultry meat products reached over £3.1 billion in 2022.

As one of the biggest food product industries globally, the spotlight is constantly on food companies that manufacture, process or distribute poultry products for sale to ensure their safety and quality for consumers.

However, according EU’s RASSF alert notifications poultry & poultry meat products where the second most recalled product category in 2023 in the continent. And as the CDC estimates that more than 48 million US citizens get sick annually due to foodborne disease, it becomes imperative that food companies pay close attention to safeguarding consumer’s health.

How can the poultry industry avoid recalls?

In order for poultry manufacturers and retailers to be able to ensure the safety and quality of their products, they need to have a comprehensive overview of all potential risks to their supply chain.

This entails being able to access and study the full food safety history of the industry in order to pinpoint trends and persistent hazards over the past years. But knowing the food safety history of the industry isn’t enough. Poultry food companies need to take a step further and capitalize on proactive measures. When creating risk mitigations plan, they need to also be able to consider the risks and hazards for their supply chain that are forecasted to increase. This way they can move from a reactive to a proactive stance.

How can this be accomplished?

Utilizing FOODAKAI, the AI-powered food risk intelligence platform, we decided to take a quick look into the food safety history of the poultry industry, while looking ahead to what is forecasted for the future.

A brief history of food safety for the industry

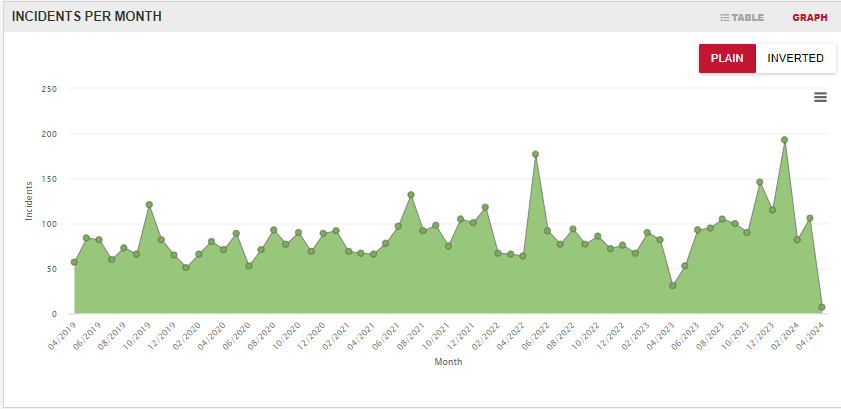

Over the last 5 years 5.398 incidents have been recorded for the product category, with 2 significant peaks in the number of incidents, the latest of which in January 2024 due to Listeria monocytogenes incidents in turkey from France.

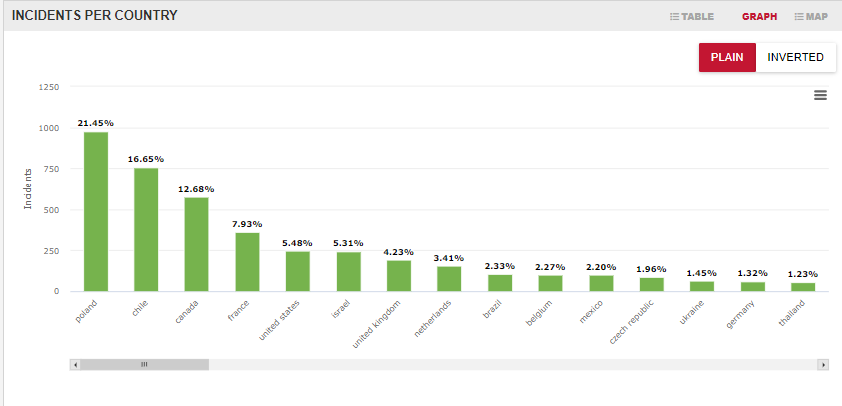

However, the product with the most incidents over the last years was chicken, with 1.943 incidents. Poland was highlighted as the country that contributed to most incidents recorded for chicken, amounting to 21.45% of the total number of incidents. The hazard that was illustrated to be most present in incidents related to chicken products from Poland was Salmonella enteritidis.

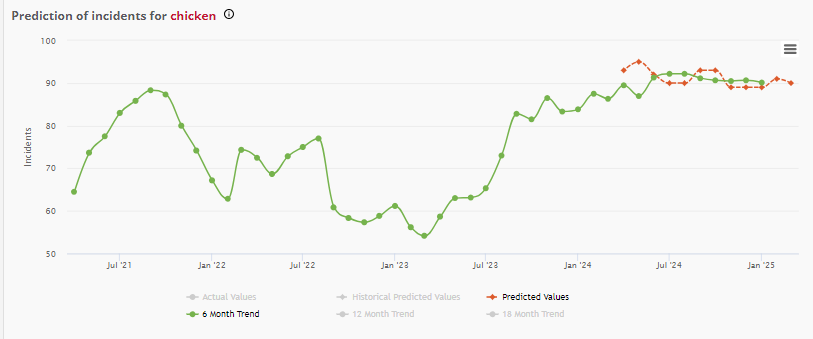

Forecasting Risk

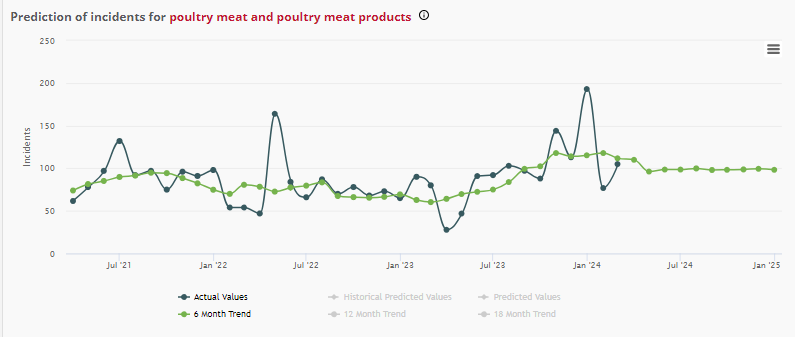

A slight increase of 3% in the number of incidents is forecasted for the overall product category with France forecasted as the higher risk country. It should be noted that while there is only a 3% forecasted increase in the number of incidents, Salmonella spp incidents for Poultry products is forecasted to increase by 21.05%.

Chicken incidents are forecasted to increase by 22% over the next months with Poland highlighted as the country with higher risk. Similarly to the overall Poultry category, chicken incidents attributed to Salmonella spp. are forecasted to increase by 20.87%.

Over the next months, Salmonella spp incidents are forecasted to increase for the overall Poultry Product category.

While there seems to be a decrease in the number of incidents in the future for the overall product category, the incidents trends for chicken are expected to increase, with Salmonella spp. as the prime suspect. This stands as a great indication of how a combination of both historical data and forecasting can offer a comprehensive overview of the food safety risk for each product in their supply chain. With such information on both the food safety history of all products as well as actionable insights on what risks and hazards are projected to increase in the future, food & beverage companies can formulate robust risk mitigation strategies that capitalize on proactive measures.

One size doesn’t fit all, so let’s set up a dedicated session with one of our consultants tailored to your supply chain.

Want to receive helpful food safety intelligence in your inbox?