How to be proactive against unexpected threats to your supply chain

Often, news breaks out of massive contamination of a number of food products that forces large food retailers to recall their products from multiple markets around the globe simultaneously. They rush to pinpoint the exact source of the contamination and its scale throughout a complex supply chain which might require days of efforts to remove products that don’t meet the safety requirements for consumption.

While food retailers strive to ensure public health through the offering of high-quality products, they don’t always have a complete overview of what’s happening across their supply chain and all risks that might affect it. As a result, they can be left exposed to food safety incidents which, besides consumers health, can gravely impact food companies’ business continuity, reputation and sales as they address and incident.

Faced with the reputational and economic ramifications of a food safety incident, food retailers need to adopt a more proactive rather than reactive stance to unexpected threats and food fraud cases.

The challenges of knowing all risks to your supply chain

Being proactive about potential food safety incidents requires an expanded and clear overview of all risks that can impact your supply chain. However, knowing where and how your foodstuff can be compromised throughout the whole length of complex supply chain can be a disarming task for food retailers. When it comes to knowing all the risks and having reliable view of how they can affect their ingredients and finished products, food retailers often tackle issues such as:

- The necessity of ensuring the authenticity (geographical and botanical) of all the ingredients and products, especially since consumers are becoming increasingly more aware of the issue, ardently requesting authentic high-quality products.

- The need for large scale continuous inspections and lab tests to make sure that all supplied products are provided to consumers with a full product ingredients list without any potential harmful omissions or mislabeling, avoiding food fraud (products that contained allergens that were not included in the label).

- The difficulty of analyzing, harmonizing and correlating food safety data from various disparate sources (third party solutions, suppliers from around the world, regulatory bodies) into actionable insights about potential risks to their products, especially since regulations are becoming increasingly stricter.

- The reliance on paper documentation and limited adoption of digital documentation of food safety and quality check procedures, despite urgent need for digitalization in order to promote transparency.

- The lack of a comprehensive and customizable system that collects and correlates information centrally but can also cater to the different data/informational needs of various food retailer departments or locations (teams in different territories require different suppliers and ingredient data) by allowing for data segregation and customization according to specific needs.

- The positioning of food retailers as the last line of defense to safeguard public health highlighting their increased responsibility to review and discover products that don’t meet the health requirements for consumption before products are promoted to consumers.

- The added risk of ensuring the product safety of supplied fresh, raw materials, since their increased consumption due the promotion of a healthier lifestyle.

From reactiveness to preventiveness

With public health in mind, food retailers need to prioritize on strengthening their procedures and protocols, and enhancing internal audits by acquiring a more reliable view of all threats to their ingredients and finished products so they can avoid a food safety incidents and fraud.

Heralded as one of the solutions that can have multiple applications in food safety, AI technology and predictive analytics can be utilized by food retail companies in their efforts to identify and respond to risks quicker. Tappin into AI, a food company could benefit from:

- Improved traceability and transparency throughout their supply chain via the concentration of all food safety incidents and data in a single unified platform that notifies you of food safety events anywhere in the world so you can recall your products, adhering to the increasingly strict traceability rules and need for digitization.

- Continuously updated food safety insights based on high-quality data from public food safety authorities.

- Advanced hazard analysis on all your raw materials and final products that allow you to have an overview of all food authentication aspects of the foodstuff.

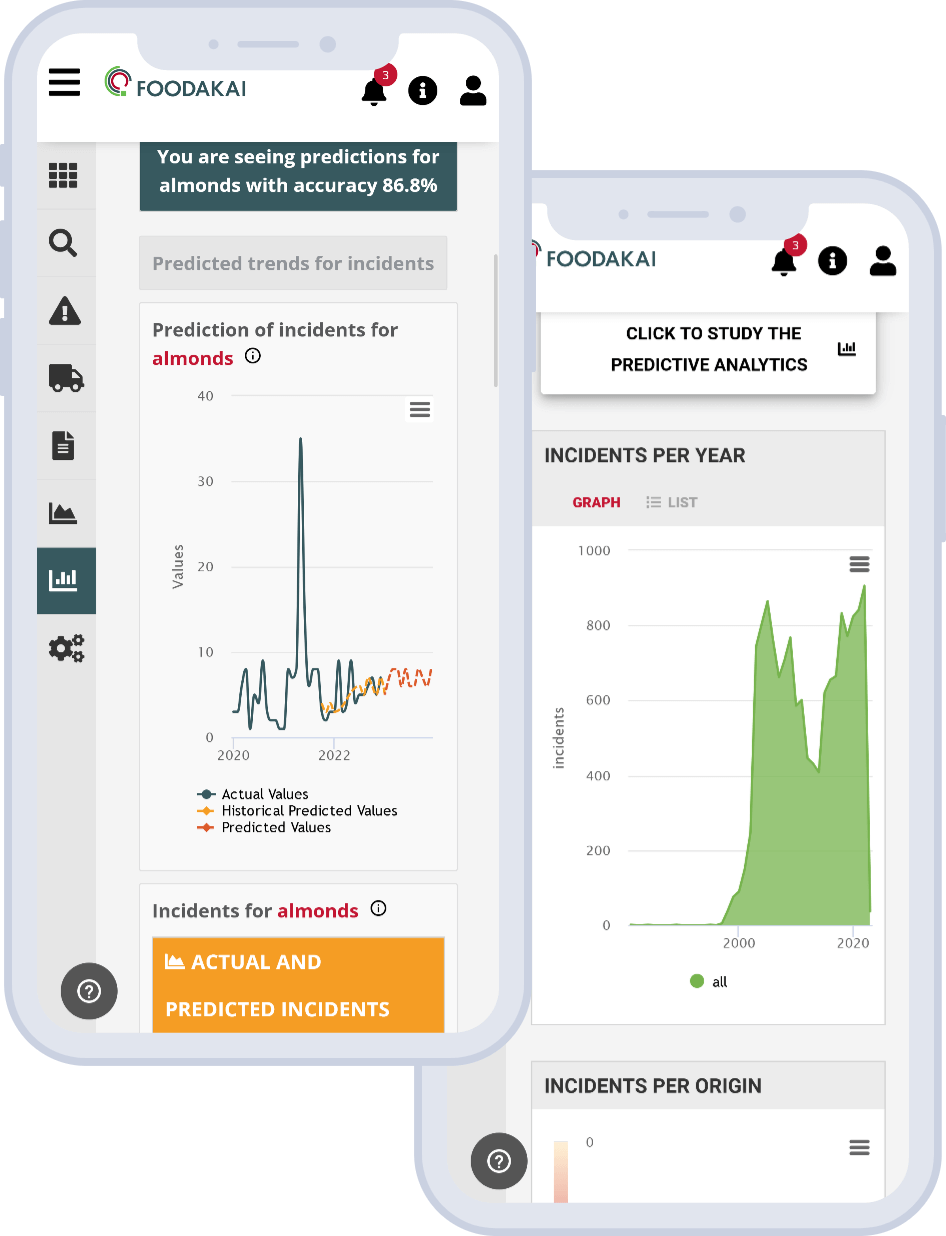

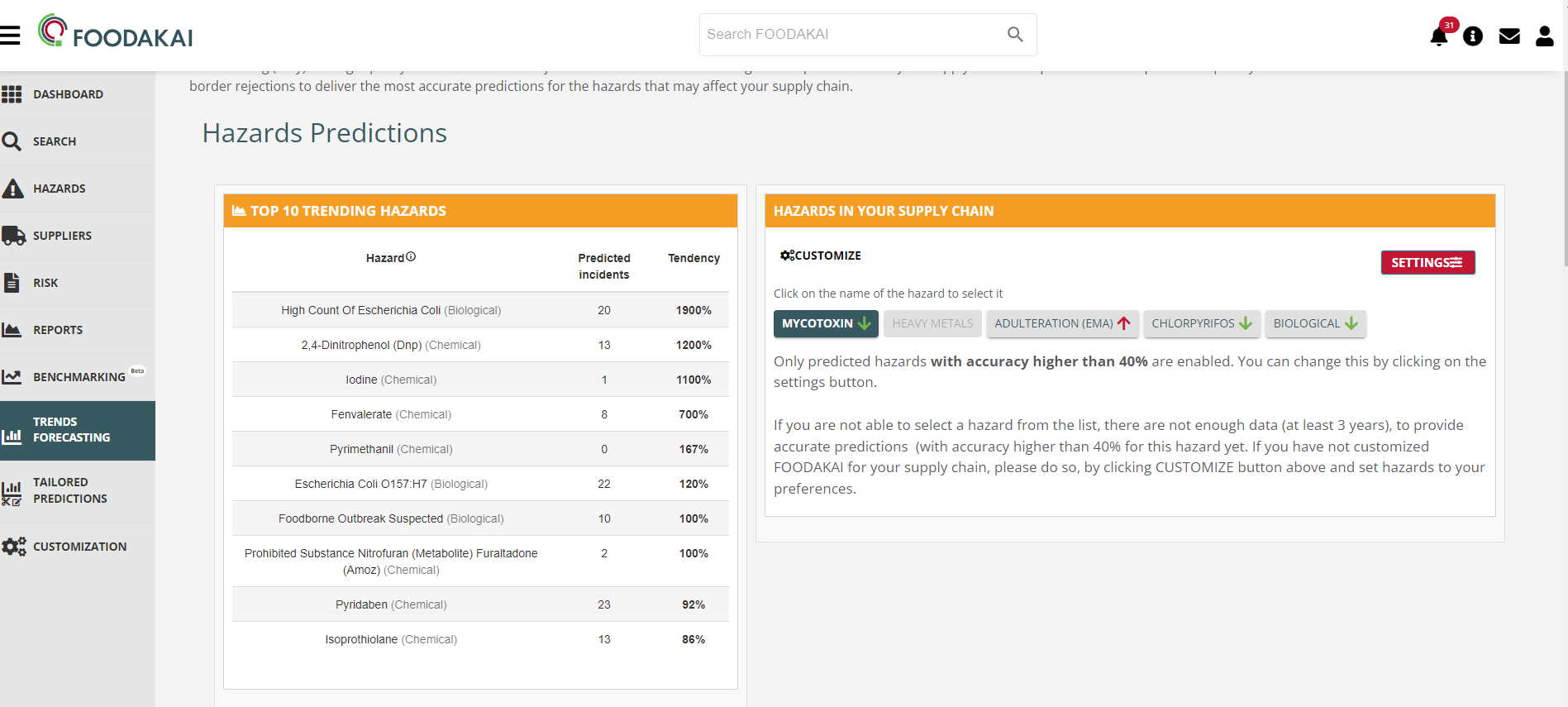

- Reliable and highly accurate forecasts for future food safety events for specific raw materials and ingredients for specific geographical areas.

- Enhanced supplier risk assessment and evaluation factoring in the risk estimation for each ingredient or raw material sourced, as well as the geographical origin of the supplier.

- Enhanced sustainability efforts and meeting goals by reducing food waste and providing safe products.

Utilizing an AI-powered solution that provides actionable insights from high-quality data can greatly empower your decision-making process. Through elevated suppliers’ assessment based on their risk performance from past incidents, ingredients sourced, and geographies evaluate existing suppliers and select new ones according to their performance.

Through forecasts trends on incidents and hazards for specific raw materials and products, food retailers can discover the products or geographical areas with higher risk as well the associated supplier they source from in these areas and take preventive measures. With total overview of emerging risks to their supply chain risk managers can formulate a comprehensive lab plan strategy, increasing inspections of their suppliers and/or internal audits.

FOODAKAI’s AI-powered platform offers actionable insights based on high-quality from more than 190 public food safety authorities worldwide and highly accurate forecasts on emerging risks that empower risk managers to create a comprehensive risk mitigation strategy. Through the platform’s intuitive forecast and supplier assessment dashboards discover potential threats to your supply chain, risk areas and products and take measures to avoid food safety incidents by removing products that don’t meet health requirements before they reach the shelves.

To find out more about how FOODAKAI enables you to take more preventive measures against emerging risks in your supply chain, begin with a pilot.

Book a call with us today!

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme STELAR (Grant Agreement Number 101070122). Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.