Leveraging LIMS and AI to enhance food safety measures

The universally known saying “prevention is better than cure” rings truer than ever in the Food Industry. According to recent studies the number of recalls in the food industry has significantly risen in the past years. The U.S. Public Interest Research Group found that the number of recalls issued in 2023 was 8% higher than in 2022. On top of that, consumers are increasingly scrutinizing the origin but also the quality of products they consume, paying more and more attention in the transparency of the food supply chain.

It is therefore becoming more and more evident that a shift is needed towards greater proactivity but also transparency in safeguarding consumer health. This is exactly where Laboratory Information Management Systems (LIMS) can act as an ally for food businesses, offering the necessary tools to enhance product testing processes, interpret data effectively and of course, mitigating risks before they escalate into recalls.

Laboratory product testing in the ever-evolving landscape of food safety hazards, from microbial spoilage to chemical adulterations, can be a tricky task for food businesses. In today’s world one’s laboratory testing plan must not only meet regulatory requirements but also anticipate potential risks before they “materialize”. The focus again needs to be on staying proactive.

At the core of proactive testing is the ability to extract useful insights from large datasets generated through laboratory analysis. And this is where LIMS becomes crucial for a food business. By gathering and organizing lab tests in one place, LIMS act as an enabler for food businesses to spot patterns, recognize trends and pinpoint any irregularities in the results.

Consider the following scenario: A food manufacturer conducts routine microbiological testing on its production line. With LIMS each test result is logged and cross referenced with historical data. If a sudden spike in microbial counts is detected, LIMS can act as a means of alerting quality assurance teams, enabling prompt investigation and intervention if necessary.

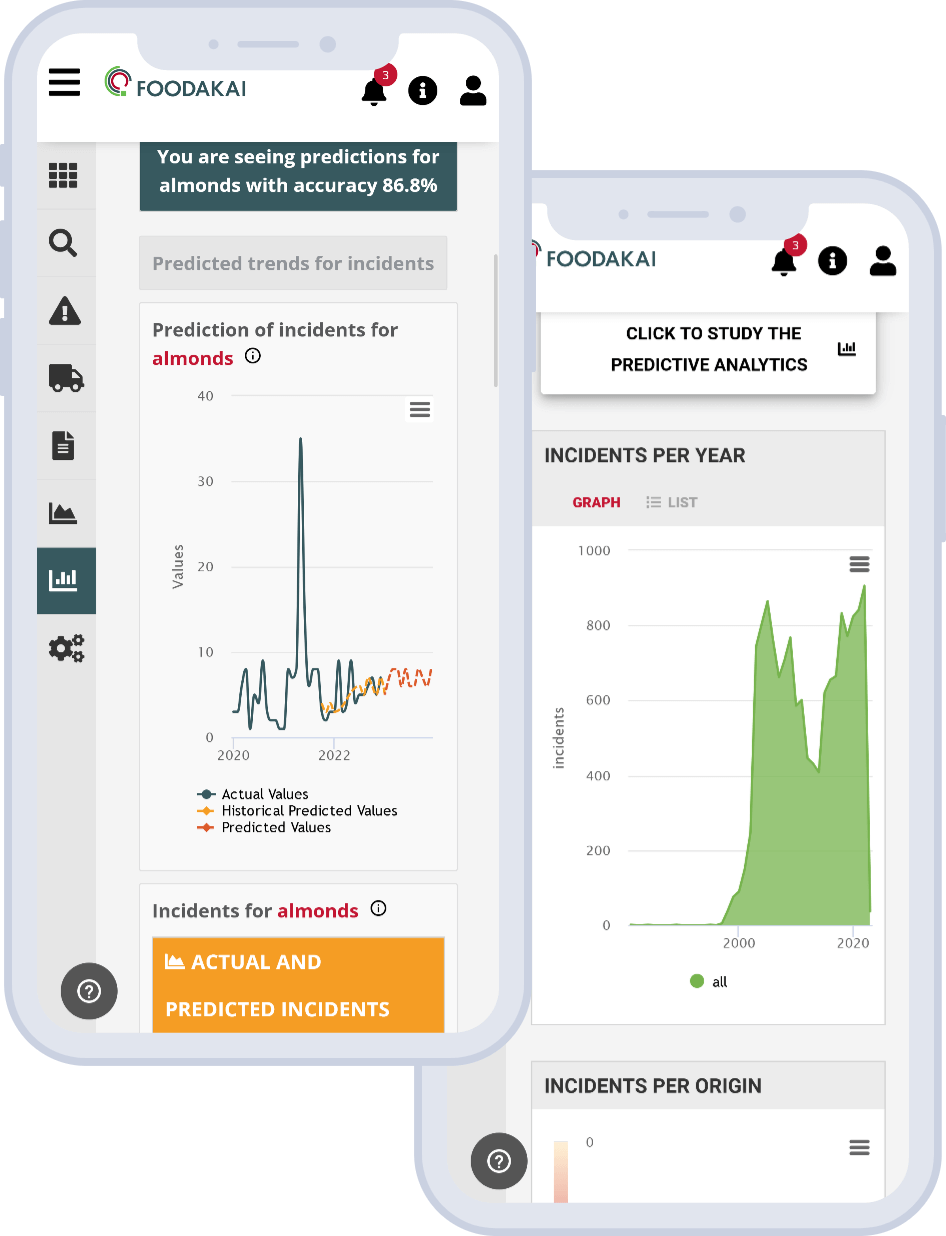

While LIMS can act as the backbone of effective data management, harnessing the full potential of laboratory data requires a sophisticated analytical tool as well. This is where a platform like FOODAKAI can step in. By integrating LIMS with FOODAKAI the power of AI can be used to extract actionable insights from testing data. Considering the additional features of FOODAKAI, by analyzing historical incident trends, food businesses are enabled to stay ahead of emerging risks and anticipate future challenges gaining a more holistic approach to food safety intelligence.

In conclusion, the adoption of LIMS is more than a matter of regulatory compliance. By investing in such a system, companies can transform their testing plans from reactive to proactive ultimately safeguarding consumer health and fortifying their brand. The “fusion” of FOODAKAI and LIMS doesn’t just revolutionize laboratory data management, it can really empower food businesses to navigate the landscape of food safety with confidence but also with a touch of ingenuity.

Share your feedback on FOODAKAI's LIMS solution!