Incorporating Predictive Analytics in Supplier Risk Monitoring and Assessment

Two weeks ago, Agroknow and FOODAKAI had the pleasure of hosting an enlightening webinar on the application of AI and Predictive Analytics in Supplier Risk Monitoring and Assessment.

The webinar’s host, Nikos Manouselis, Agroknow’s CEO, joined Takiyah Bull, Food Safety Microbiologist at Sargento Foods Inc., Denis Treacy, Former Chief Officer for Safety and Quality at Pladis Global, and Mihalis Papakostantinou, Head of Data Services at Agroknow.

The main question that was posed for them was: how can an AI and predictive analytics help influence suppliers food safety performance.

Among the topics that were discussed were:

- the perception of AI and predictive analytics regarding food safety.

- How AI can enable better decision making in working with suppliers for risk monitoring and assessment.

- 3 Uses Cases of how predictive analytics can improve supplier monitoring and assessment.

- If AI and predictive analytics can be practical and useful solution for food companies.

Key Takeaways

During the 1-hour discussion between the four panelists, they went on to discuss about AI and predictive analytics and how they can strengthen food companies and suppliers relationships as well as reflect on the actual use of such technology with 3 Uses cased from FOODAKAI’s AI-powered platform.

What was most highlighted was:

- 50% of the webinar’s audience voted to be neutral about understand and trusting AI technology in poll conducted live.

- Understanding what industry experts need to know about their suppliers to have a successful business relationship with them.

- Noting the importance of knowing more about food companies’ suppliers risks and vulnerabilities in their sectors in order to better formulate mitigations plans and maintain a repeatable and predictable supply chain.

- 75% of the webinar's audience voted that AI should help companies start testing for emerging contaminants in their supply chain.

- Utilizing predictive analytics and AI to enhance knowledge and insights on supplier’s risks to gain a competitive advantage.

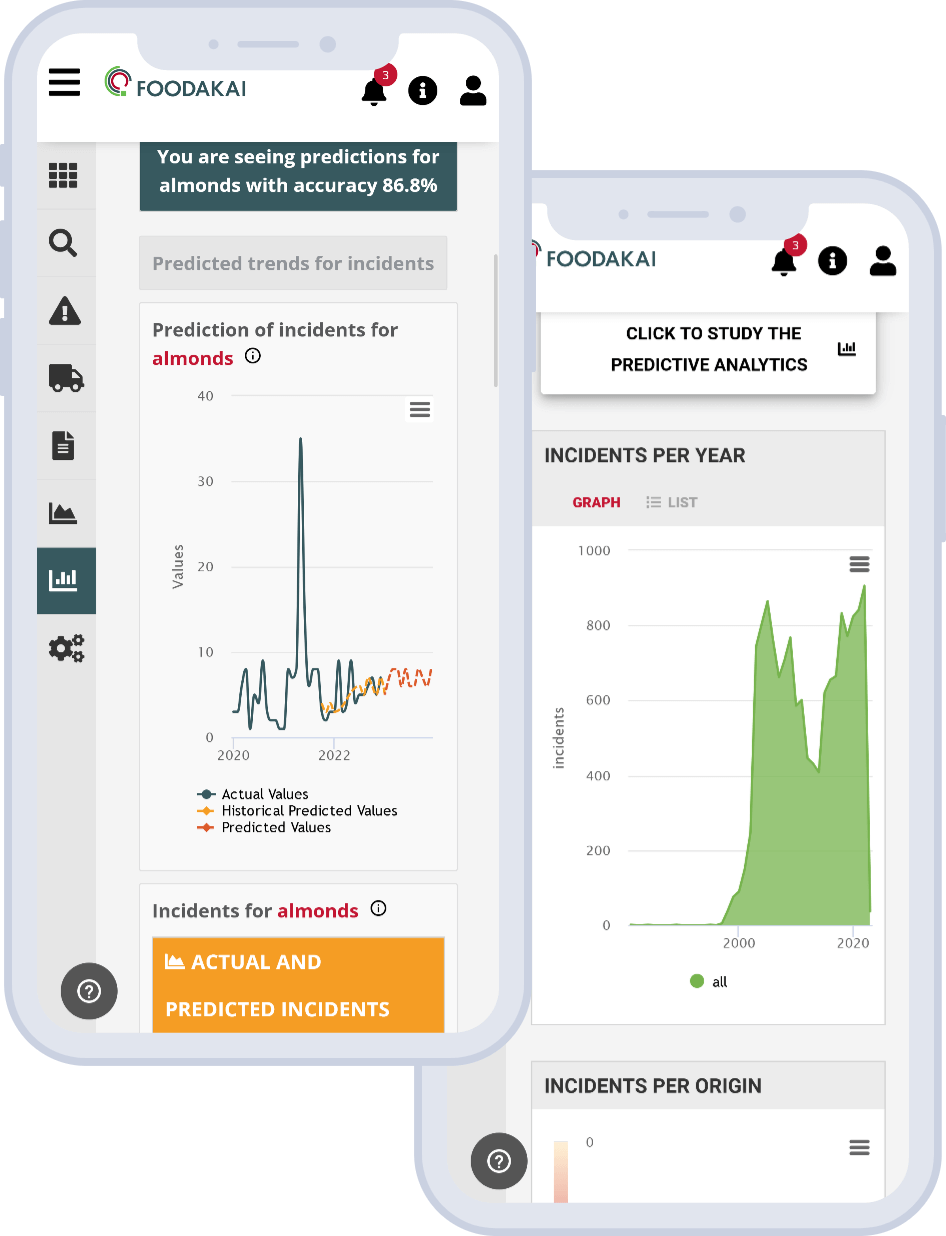

- FOODAKAI’s offerings of forecasts on suppliers and geographies with increasing risk as well as integration of forecasts in Supplier Management Platforms through 3 analytical use cases.

FOODAKAI’s Forecasts on Supplier Risk Use Cases

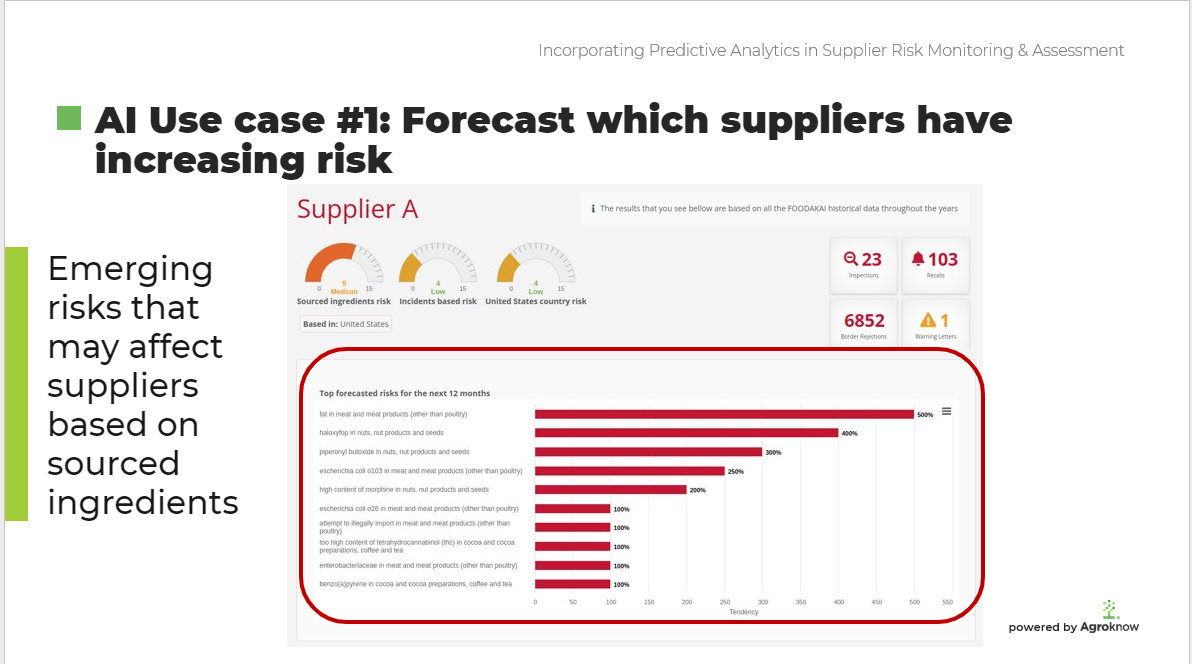

Forecasts on Suppliers with Increasing Risk

Through FOODAKAI’s live risk Suppliers Profile, food companies can have an overview of the Suppliers food safety performance calculated based on their risk as it relates to their sourced ingredients, number of incidents and country of operation. Additionally, they can drill down further by selecting to see the Inspections, Recalls, Border Rejections and Writing Letters.

Food companies can access forecasted risks on the top hazards that are expected to be on the rise for their key ingredients they might be sourcing from the specific supplier. Thus, they can identify emerging risk to their supply chain based on sourced ingredients from suppliers and formulate a more focused lab testing strategy.

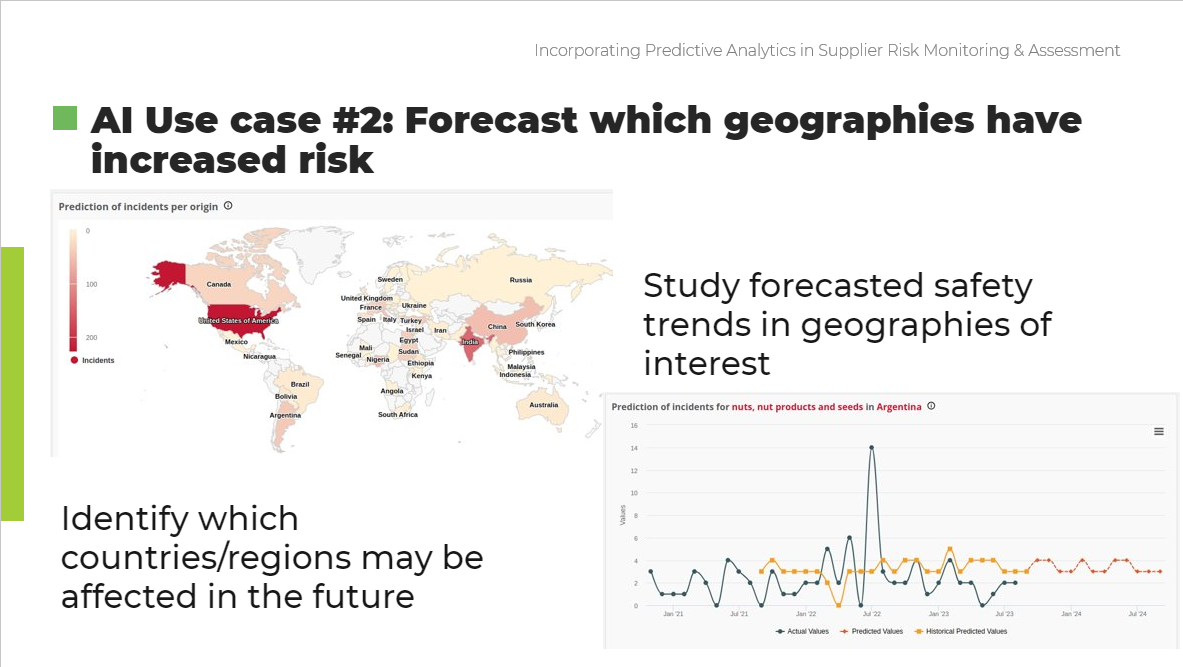

Forecasts which geographies have increased risk

Using FOODAKAI’s ingredients and hazard forecasts food companies can study forecasted safety trends in geographical areas of interest for their selected ingredient or finished product. They can discover which of these countries are expected to have increased risk for incidents for their key ingredients which are sourced there or suppliers located in the area.

With this data they can have a greater understanding of the expected risk for their regions of interest and for specific ingredients, evaluating their risk profile and taking preventive measures to avoid recalls.

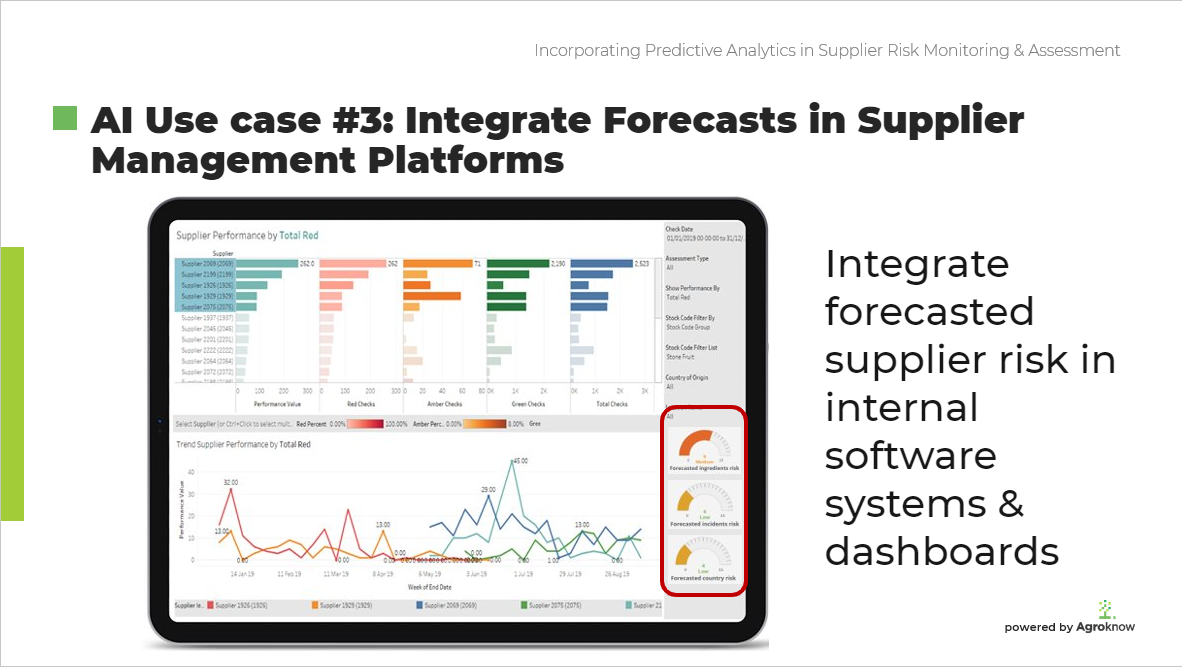

Integrated Forecasts in Supplier Management Platforms

Having high quality historical data that will help us determine which suppliers and for which sourced products are expected to have increased risk of incidents, as well as the regions with more expectancy for risk is vital.

However, most companies already have an internal supplier management system that they used to make their decision. FOODAKAI’s data and insights on suppliers and predictions can be incorporated in these systems. Through a streamlined and simplified integration, food companies can have forecasted supplier risk data combined with their internal data within their supplier management systems and dashboards to help Risk Managers in their decision-making process.

Want to see the full discussion. Watch below.

To know more about how FOODAKAI can boost your supplier monitoring and risk assessment and identify emerging risks in your supply chain, book a call today.