How to strengthen your food safety management systems against emerging risks

What the past years have proven is that food companies need to constantly update their food safety practices towards new and emerging risks to their supply chain. Whether global incidents (such as the Covid-19 pandemic or the war in Ukraine disrupting the global supply chain), the increasing effects of climate change, or an outbreak that leads to massive recalls worldwide, food companies need to always be ready to face unprecedented risks and shield their products.

Food safety incidents can have major ramifications not only on consumers’ health, but, also, on food companies worldwide whose products didn’t meet the hygiene standards for consumption. Such incidents can shake the consumers’ confidence in their products and lower their trust towards a company, and therefore negatively affect the food company’s brand equity.

Additionally, addressing global recalls can be an extremely expensive process for food companies due to the ensuing business interruption, food waste, loss of sales, customer reimbursement etc.. Thus, the potential reputational damage and impact on the company’s market value necessitate the need for companies to be able to avoid unexpected food safety incidents and ensure public health.

The challenges of being prepared for the unexpected

With their reputation and market value in line, food companies need to be ready for an unexpected food recall, border rejection, or the effects of climate change that might affect their production. Risk managers’ incident mitigation strategy can outline measures to reduce the impact of such events. However, this doesn’t instantly lead to sufficient preparedness against new, unprecedented risks that food companies often face jeopardizing the integrity of their products.

Predicting what’s to come can be extremely challenging especially taking account that many food companies tackle issues such as:

- The costly and extremely time-consuming utilization of multiple, different internal or third-party solutions to correlate data from disparate sources in order to perform ingredient and supplier risk assessment.

- The conduct expensive lab tests on limited samples of the food company’s foodstuff and suppliers, hoping to cover a large area and pinpoint potential risks, without having a clear view of what’s happening across the whole supply chain.

- The lack of high-quality actionable food safety data makes it impossible to make informed business and strategic decisions and form comprehensive risk mitigation plans against unforeseen threats.

- The vast number of raw materials, processed products, suppliers that global food companies have to track from numerous sources worldwide and through various non-customizable solutions, hurdling food traceability and transparency.

- The inherent difficulty of identifying emerging risks which can be attributed to factors like the complexity of the food supply chain, climate change, urbanization, antibiotic resistance genes of microorganisms etc..

These issues highlight the imminent need for food companies to adopt a more proactive stance against emerging risks by being able to early identify and avoid future threats to their supply chain.

How to level up your company’s preparedness against incoming, unexpected risks

Considering the impact that a food incident can have on your food company, it should come as no surprise that building your supply chains resilience against unexpected threats is paramount to ensure business continuity.

Strengthening your food safety management, utilizing rapid detection techniques for contaminants, conducting advanced risk assessment and analysis of hygiene indicators are a few solutions that can increase your product line's overall integrity and safety.

The above solutions combined with the power of AI can rapidly strengthen your food safety management systems. Implementing AI technology based on accurate clean data can significantly boost your food company’s ability to identify and forecast unforeseen risks, while increasing efficiency and cutting costs. An intelligent AI solution should allow you to:

- have continuously updated insights on global food safety events including biological, chemical and physical hazards etc. in single platform environment,

- have powerful quality data-driven forecasts trends on food safety incidents and increasing risk in specific hazards for every product or ingredient in your supply chain,

- conduct risk assessment and evaluation of suppliers based on their performance, geographical origin or ingredient and decide on additional measures,

- perform in-depth risk and hazard analysis of your raw materials and final products to discover potential risks from farm to table,

- meet your sustainability goals by avoiding food recalls and food waste.

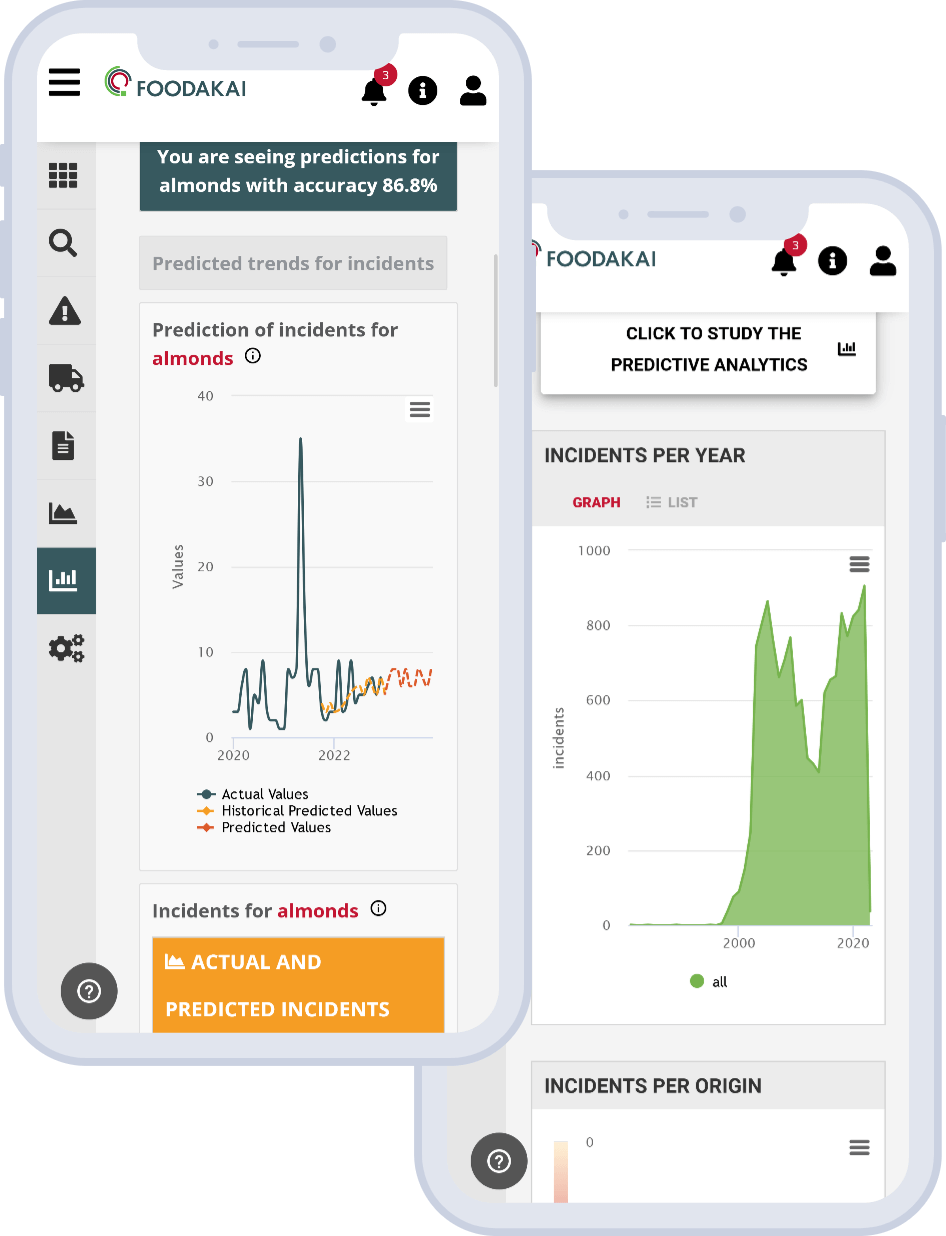

Employing a unified AI-driven platform that combines historic and predictive analytics of incidents, emerging risks and hazards and that is tailored to your food company’s ingredients will enable you to formulate a comprehensive risk mitigation plan based on actionable data, enhancing the existing food safety management systems.

With forecasts on emerging risks for your key ingredients and trending hazards to your supply line, you can optimize the lab test planning and sampling strategy to perform focused and strategic lab testing, audits and assess suppliers where most needed to ensure the safety of your products and ingredients.

In addition, with forecast trends on increasing hazards in your supply chain, you can enhance your preventive measures against incoming threats, while minimizing the cost of quality control procedures and meeting your sustainability goals by avoiding unexpected food recalls and food waste.

FOODAKAI helps you safeguard your food products against new and unforeseen threats by early identifying emerging risks. Through the platform’s comprehensive dashboards, discover forecasts for the likelihood of potential risks and hazards to your key ingredients and suppliers in a single unified environment to create a comprehensive and informed risk mitigation strategy.

To find out more about how FOODAKAI empowers you to become more proactive against emerging risks in your supply chain, begin with a pilot.

Book a call with us today!