How to enhance your monitoring of all external risks to your supply chain

With food recalls and border rejections happening every other day it stands to say that food retailers need to be on high alert for a recall. Just in the first quarter of 2023 there was a 23.1% increase in food and beverage recalls in the US, a four-year high, and a 2.9% increase in Europe, followed by another Salmonella outbreak recently . Additionally, in 2022 , the total number of products recalled by the FDA increased by 700% compared to 2021. The high probability of food recalls makes it necessary for food retailers to be able to swiftly respond to an incident and ensure the circulation of safe and high-quality products.

More often than not, global food retailers face extensive food recalls that can have them rushing against time to remove unsafe for consumption food products from the shelves of stores and supermarkets worldwide. Factoring in the potential impact on consumer’s health as well as the extremely costly process of addressing a food recall (loss of sales, food wastes that backtracks their sustainability goals) and ensuing reputational damage, sets tracking food safety incidents in the most efficient way possible of the highest priority for Risk Managers.

Yet, food retailers lack a clear view of all the risks globally that can affect their supply chain making it impossible to respond quickly and avoid a recall.

What makes having a complete overview of all risks challenging?

At a time when customers’ trust towards global food companies is being constantly tested due to frequent food safety incidents that jeopardize public health, food retailers struggle to have a clear picture of all risks that affect their supply chain. While trying to ensure that their products meet safety standards for consumption, they often face issues that impede their mission to offer high quality products and leaves them exposed to risks such as:

- the overload of data collected from disparate sources through the application of internal and costly third-party solutions that are impossible to analyze, harmonize and correlate into actionable insights about risks to their supply chain.

- the reliance on complex paper documentation on food safety and quality checks as well as suppliers checks and not on digital documentation, reducing the speed with which a recall can be defined, decisions made and executed.

- the different data/informational needs of various food retailer departments or locations (different territories require data on different suppliers and ingredients) are not met due to the lack of customizable solutions that would offer data to cater their specific needs.

- the complexity of the supply chain, which despite the traceability procedures set, can lead to downstream companies be late to be notified for several days, weeks, or even longer of a food safety incident and corrective actions be delayed.

- The limited view of what’s happening across their supply chain makes it difficult to perform quality control practices on specific high-risk ingredients areas to discover potential risks.

- The sourcing and offering of products from various supply chains means that it is difficult to track all quality & safety parameters information.

- The increased risk and importance of ensuring the high quality and safety of supplied raw materials by food retailers, especially since the growing adoption of a healthier lifestyle that promotes their consumption.

These challenges illustrate a necessity for Risk Managers: to be able to have a comprehensive, reliable view of all threats globally that might impact their supply chain. This way, appropriate corrective measures can be placed to ensure that damage is minimized.

How to have a total overview of all risks to your key products

Food retailers, considering these challenges and the impact of food safety incidents on business continuity, should utilize advanced solutions that allow them to respond to food safety incidents more quickly and effectively.

Harnessing the power of available food safety data in combination with AI algorithms can be a great steppingstone towards improving the tracking of high quality and safe food products from farm to table and thus providing consumers with greater transparency and accountability. A comprehensive AI solution could offer the ability to:

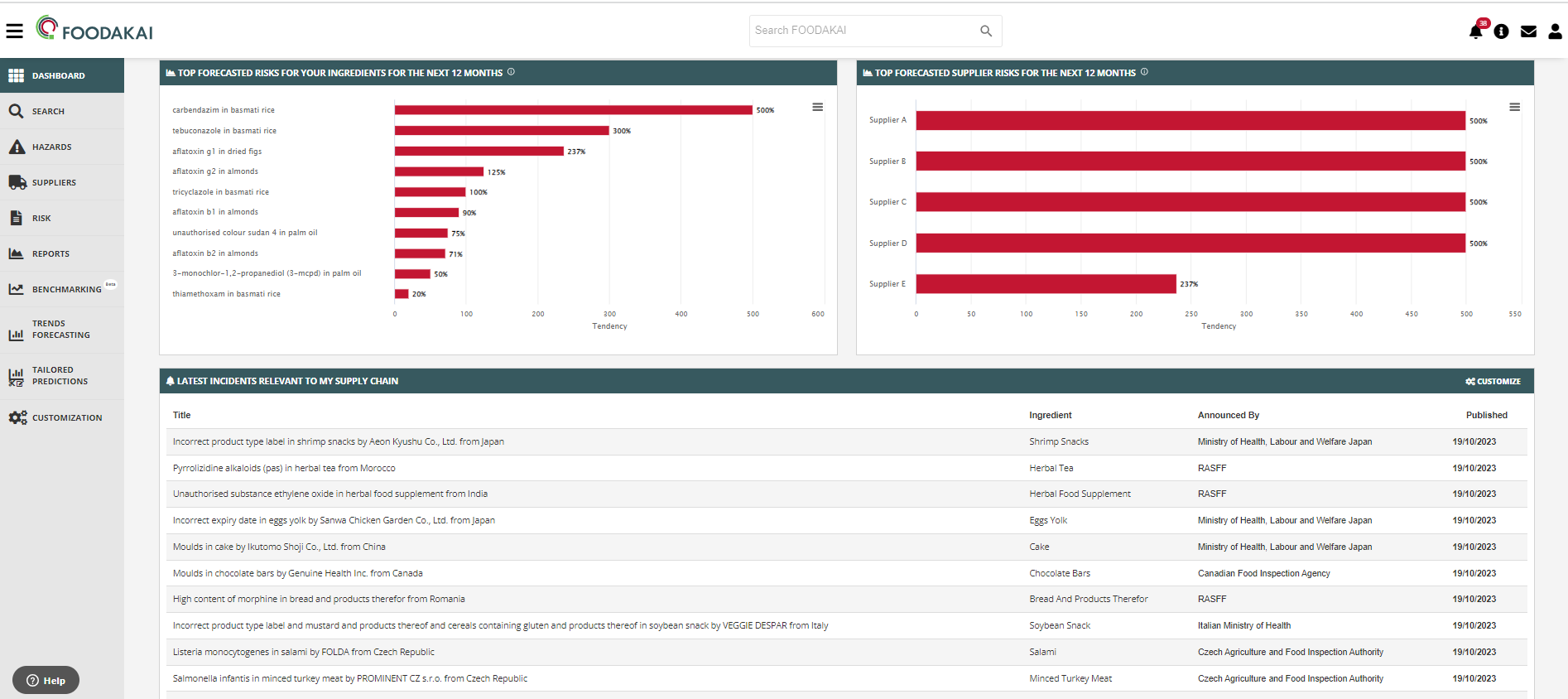

- Quickly be notified of food safety incidents concerning any of your sourced products from any of your suppliers.

- Remain continuously updated on global food safety and food fraud events (including recalls, border rejections, food fraud, adulteration, mislabeling,) that can potentially impact your supply chain, identifying weaknesses.

- Perform in-depth risk assessment and hazard analysis on all your key raw materials and food products, allowing you to set risk mitigation strategy.

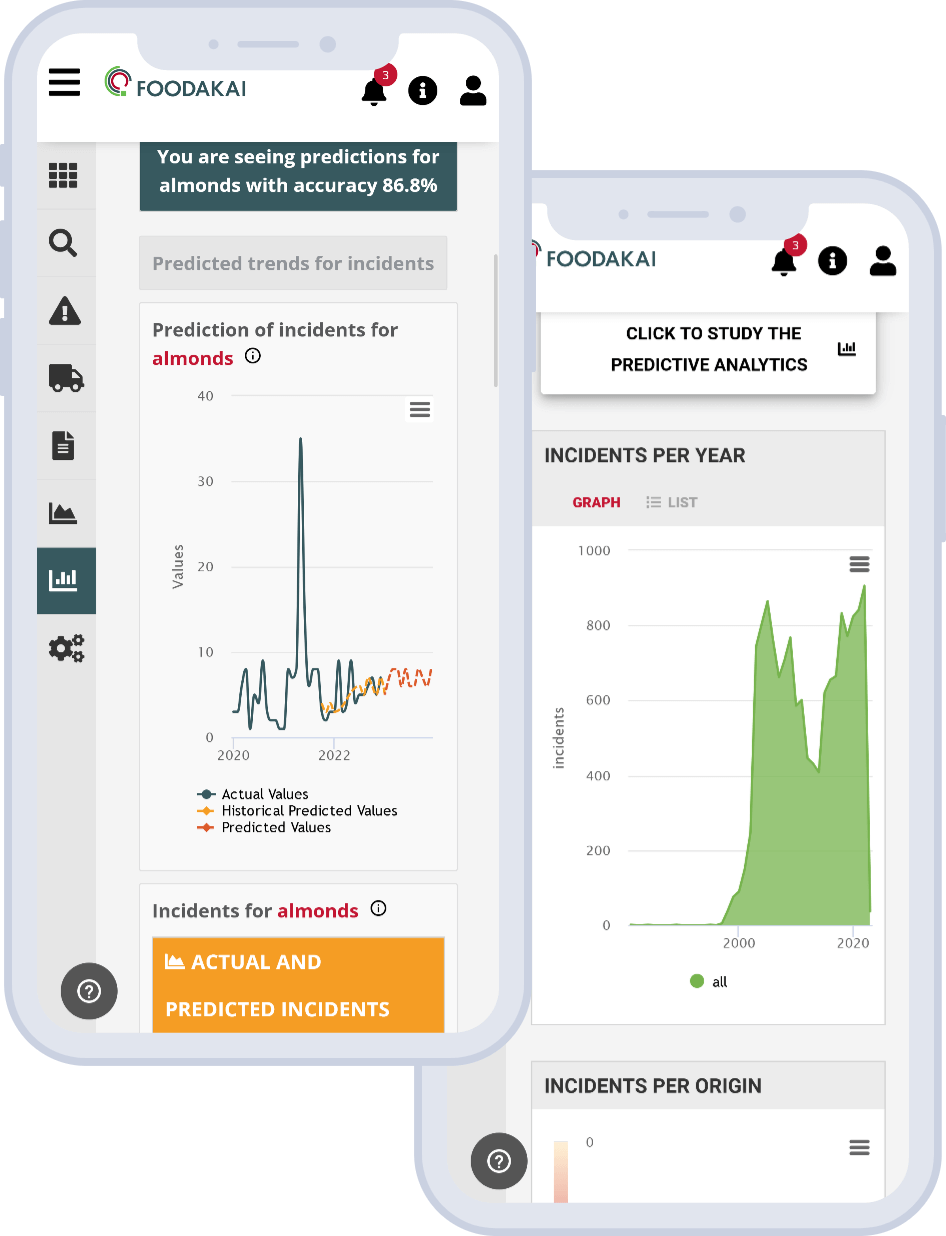

- Access forecasts on hazard trends (chemical, biological, physical and allergens) and vulnerable products, including key ingredients and foodstuff that can influence your Risk Managers’ decision-making process.

- Meet your sustainability goals by reducing food waste.

- Reduce costs by strengthening the food products and suppliers’ risk assessment processes through a unified solution.

- Perform more focused risk analysis practices on specific high-risk areas.

- Ensure the validity of the information of the final product (geographical origin, authentication, safety etc.).

Through an AI-powered platform that offers always-updated insights on food incidents around the world, perform real-time incident monitoring and so that you can quickly respond to a recall about any product. With enhanced customization that allows you to tailor the platform to each team’s needs, get notified on the latest insights from global food safety and fraud incidents anywhere in the world and for any of your private-label products.

Selecting a unified platform that provides continuous raw materials and final products risk assessment and hazard forecasts on your key products and ingredients, per department and geographical origin, will allow you to perform more focused lab testing, and steadily move from being reactive to preventive.

Dynamically allocate your risk mitigation priorities and budget to these risks that have higher probability based on forecasts, while supporting your sustainability efforts by avoiding costly recalls and food waste.

FOODAKAI’s AI-powered dashboards allow you to have a comprehensive, reliable view of all risks to your supply chain. Perform real-time monitoring with continuously updated insights on incidents to rapidly respond to an announced recall anywhere in the world for any of your products.

Discover more about how FOODAKAI can help you become more preventive to risks in your supply chain rather than reactive with a pilot.

Book a call with us today!