How can regional food manufactures improve critical food safety processes?

As the food safety threats landscape is constantly changing and food safety-related incidents make headlines almost every other day, food companies need to continuously be on high alert for announced recalls, border rejections, food fraud cases etc. In their efforts to provide safe and high-quality products to ensure public health, food and beverage companies strive to be on the lookout for food safety incidents, hoping to avoid a larger-scale recall that could lead to loss of sales and reputational damage.

However, food & beverage companies that might have limited resources and budget often struggle with performing critical ingredients, products and supplier monitoring and risk assessment tasks at the level that larger food companies do. They rely on manual and time-consuming risk monitoring and assessment procedures that require a lot of effort and time with uncertain results leaving little time for comprehensive and strategic risk planning.

Responding reactively to incoming announcements of food safety incidents, they are in need of a cost-effective solution that would allow them to automate these processes and keep up with the ever-changing threat landscape.

The Challenges

With consumer’s health on the line, food companies are tasked with ensuring that all their ingredients and products meet the safety standards for consumption. This necessitates the continuous monitoring and assessment of the food company’s key ingredients and suppliers. For food companies with limited resources, this can an extremely laborious and difficult task owing to factors such as:

- The lack of real-time overview of all announced food safety incidents regarding their key ingredients and suppliers through a unified alerting system rather than the manual research/subscription on various public authority websites (FDA, RASFF) which can reduce the time to identify & respond to incidents.

- The reliance on manual and time-consuming processes for incident monitoring and assessment such as the use of multiple spreadsheets for the collection of food safety information from various public sector and news websites which are very difficult to compare and correlate into actionable insights to inform their decision-making.

- The lack of a comprehensive and customizable solution that collects and correlates all critical food safety information from all publicly available sources in a single environment that would prevent FQ teams from missing out on vital insights while enabling them to empower their strategic thinking.

- The shortage of high-quality and actionable data for the risk monitoring and assessment of the performance of suppliers that would allow them to better select and decide on additional preventive measures for key suppliers in their supply chain.

Automation through the application of AI

The challenges above adamantly highlight the fact that food & beverage companies would greatly benefit from the digitalization and automation of their most critical food risk intelligence processes. Implementing a unified solution that utilizes AI technology in order to collect all vital food safety information can greatly enhance food and beverage companies' risk monitoring & assessment capabilities contributing to the reduction of time allocated to these by automating them. An intelligent AI solution could allow food companies to have:

- real-time monitoring of emerging threats through the collection, correlation and curation of all food safety incidents available online by public sources.

- tailored food safety incident alerts to their supply chain, being notified according to the frequency preferences, avoiding generic alerts for not in scope ingredients or suppliers.

- in-depth hazard analysis of every single ingredient in their supply chain, down to hazard type.

- the ability to historically search through all food safety incidents regarding their key ingredients or suppliers.

- overview of all food safety incidents their suppliers have been involved in to make informed supplier selection and assessment.

- highlights on merging threats to your supply chain

- all team members, no matter the size of the company, having access to valuable food safety risk intelligence and be in sync across the company.

Utilizing a unique solution that harnesses the power of AI to provide actionable food safety risk insights based on high-quality data tailored to your key ingredients can greatly reduce your incident identification and response time.

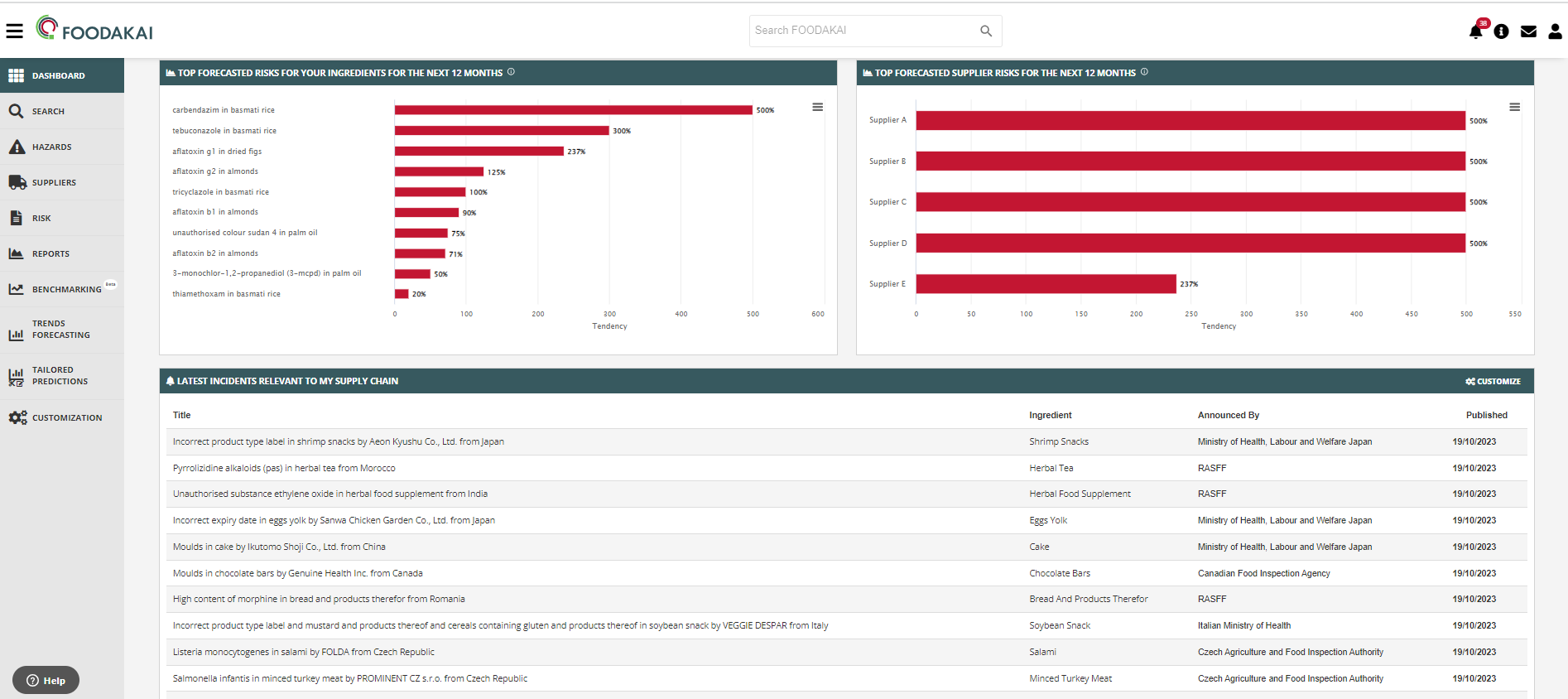

Have all necessary food risk intelligence collected, correlated, harmonized as well as curated by food safety specialists in English while removing duplicate incidents from different sources in easy-to-use and customizable dashboards. With no cap in users (unlimited) allow all team members in your company to benefit from enhanced automation without going over budget.

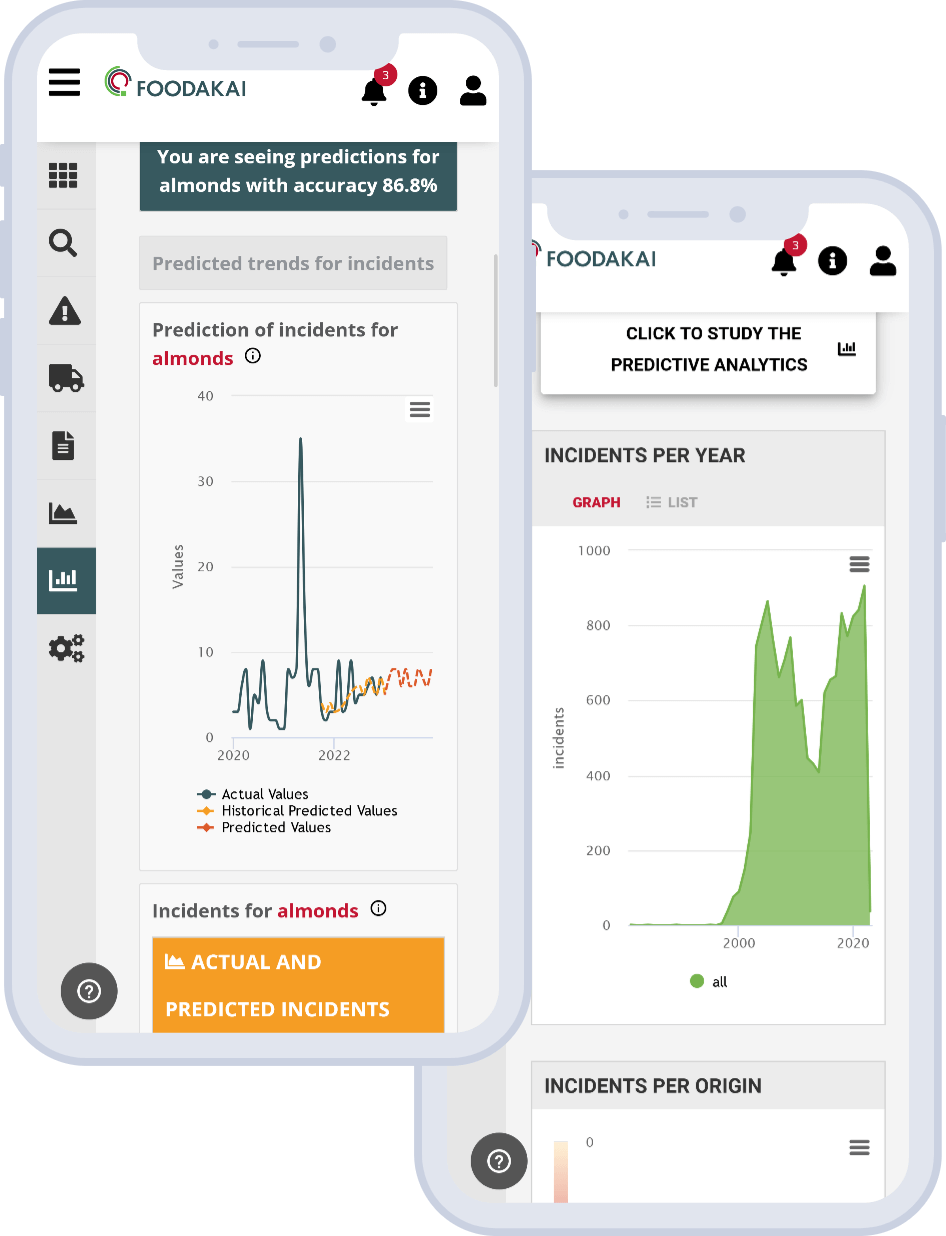

FOODAKAI, the AI-powered platform, provides you with real-time monitoring of emerging threats and incidents with notifications and alerts specifically for your products and suppliers without being bombarded with hundreds of notifications for incidents that are irrelevant to your supply chain.

Empower your ingredient risk assessment by performing in-depth hazard analysis of all your ingredients in minutes discovering the most common hazard types (physical, chemical, biological, allergens) and the geographical areas with higher risk for them. Additionally, through the FOODAKAI platform, have a complete historical overview of all incidents your suppliers have been involved in to inform your supplier selection and assessment processes.

To know more about how FOODAKAI can automate critical food safety intelligence processes while enabling you to formulate a comprehensive mitigation strategy with a budget-friendly solution, click here to download our products brochure.

Want to receive helpful food safety intelligence in your inbox?

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.